12. Check all clearances closely to make sure that nothing

will “crash” when the power is turned on and the rotor starts

rotating. NOTE: It may help to loosen the arbor nut slightly

and manually turn the rotor by hand to check all clearances.

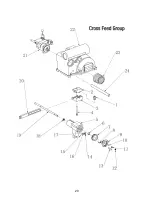

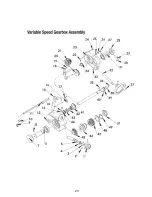

13. Adjust the drive belt to match the rotor size.The speed of

the spindle is adjustable by changing the position of the V-belt

pulley at the rear of the lathe. See page 17 for adjustment pro-

cedure. Use the outer pulley groove (FASTEST SPINDLE

SPEED) for passenger car and most light duty truck rotors.

Choose one of the inner pulley grooves (SLOWER SPINDLE

SPEEDS) when machining medium duty and larger truck

rotors and some solid rotors.

13. Before turning the power on, make sure both speed

setting handles are in their neutral positions.

14. Turn the lathe ON.

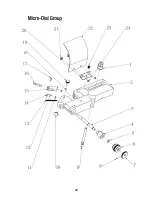

15. Turn each tool bit control (the outer knurled knobs)

clockwise until the tool bits just barely contact the rotor

surfaces and makes a slight scratch cut. NOTE: The dial

locks for the micro-dials must be loosened before

adjustments are made. After required adjustments are

made, re-tighten dial locks to hold cutting tips secure.

KEEP HANDS clear of moving parts at all times. Keep

hair, loose clothing, neckties, shop rags, jewelry, fingers,

and all parts of body away from moving parts.

Always wear safety glasses or a face shield. Cutting an

exposed surface such as a brake drum or rotor will

produce flying chips and debris.

16. Examine the scratch cut making sure it is uniform around

the entire circumference of the rotor. If the scratch cut

appears to be deeper on one side of the rotor and not a

uniform depth, then turn the power off, remove the rotor from

the arbor, check the mounting adapters and arbor for nicks,

burrs, or chips, remount the rotor, and repeat the process.

17. Check to make sure the

spindle lock knob

and

micro-dial lock knobs

are tightened before continuing.

18. Hold the outer knurled knobs firmly with your left hand,

then carefully rotate the inner knurled dial indicator knobs

clockwise with your right hand until ZERO is positioned at

top dead center and lined up with the tick mark. This will give

you an initial zero-set starting point.

15