4. Be sure that a proper tool bit is secure in the boring bar

and the cutting tip is not excessively worn. Sharp cutting

tips must be used at all times. A dull cutter will affect the

finish of both drums and rotors. If the cutting edge is

damaged, replace it promptly. Be sure no metal chips are

under tip when changing tips.

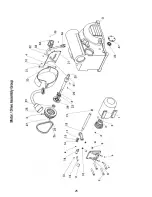

5. Mount the drum on the arbor using the proper adapters,

cones, and spacers.

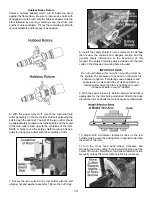

Mounting Hubbed Brake Drums

Tapered centering cones or double taper adapters fit in the

bearing seats. Be sure to make contact as close as possible to

the middle of the bearing race as possible. Various adapters

and/or spacers may be used to fill out the shaft of the arbor.

Mounting Hubless Brake Drums

Select the largest hubless adapter possible that will fit inside

the drum against the flat lug hole surface. Be sure to

straddle the bolt holes to avoid mounting against a burr, or

remove the burrs with a grinding stone before mounting.

Slip the hubless adapter onto the arbor followed by a spring,

centering cone, the drum, and another similar size hubless

adapter. The centering cone will fit into the center hole of the

drum from the inside to center the drum on the arbor. Fill out

the remaining shaft with various adapters and/or spacers

as needed.

IMPORTANT NOTE

The arbor nut has

REVERSE THREADS

. Tighten by

turning the arbor nut

COUNTER-CLOCKWISE.

IMPORTANT NOTE

The self-aligning spacer should always be used next to

the arbor nut when tightening. To avoid overtightening,

wrench turn the arbor nut counterclockwise until the

drum and adapters become fixed snug on the arbor and

so that you are unable to freely turn them. Then continue

to advance the wrench 1/4 of a turn only. DO NOT

overtighten the arbor nut.

Handle Adapters With Care

The adapters, arbor, and spindle are made

of top grade steel, hardened, and precision ground to

close tolerances. Great care should be taken in their use,

handling, and storage. The smallest nick or scratch can

cause incorrect drum or rotor alignment resulting in

inaccurate resurfacing.

6. Wrap a drum silencing band snugly around the drum.

Be sure it is positioned towards the right-hand edge or

nearest the open side of the drum.

IMPORTANT

- Failure

to use a silencing band will cause premature wear of tool

cutters and result in a poor finish cut.

10