RECONDITIONING BRAKE ROTORS

After the following instructions are read and understood,

obtain a scrap rotor for practice. Inspect all rotors

carefully for excessive scoring, rust ridges (at the inner

and outer circumference of the rotor), and blemished hard

spots. Any excessive wear or deformity should be noted. If

the rotor is not within acceptable limits, the rotor should be

replaced.

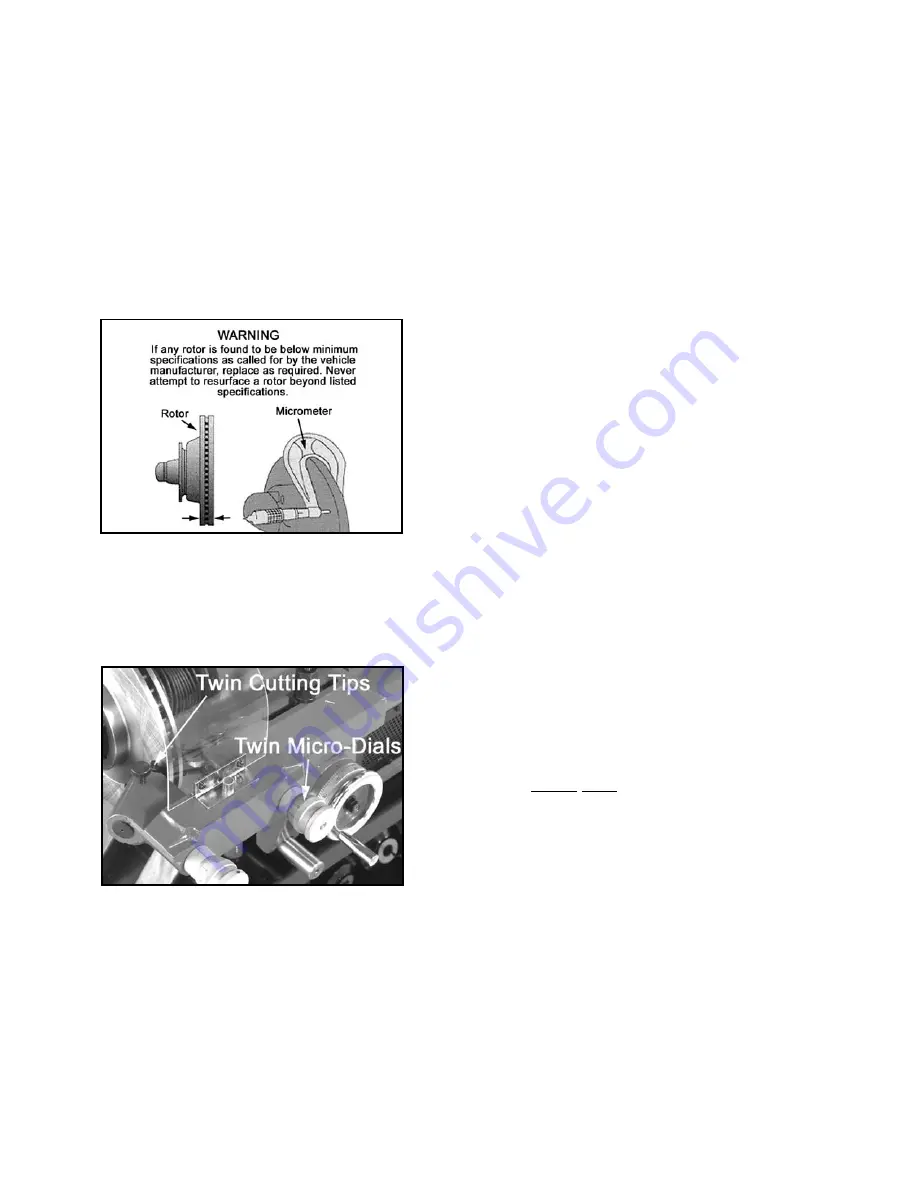

Always use a micrometer to check the thickness of the

rotor. If the rotor thickness is less than the minimum

established by the manufacturer, or if it will be less after

reconditioning, the rotor should be replaced.

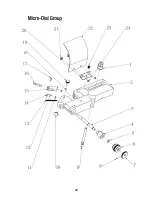

Twin Cutters

A micro-dial twin cutter tool assembly is used to

recondition both surfaces of a brake rotor at the same

time. The twin cutter replaces the boring bar on top of

the cross feed after removing the boring bar and tool

holder boring bar brackets.

Practice setting the micro-dial cutters for machining rotors.

Learn all the functions thoroughly to insure proper

operation. Most rotors will have the minimum thickness

values cast into the outer surface.

The proper procedure for determining whether to

resurface rotors or discard them is as follows:

A. Using a micrometer or some other micrometer suitable

for measuring the thickness of the rotor to be machined,

check the rotor thickness at four points (90 degrees apart)

about 1" from the outer diameter.

B. If the thickness at any of the four points is less than the

minimum established by car manufacturers as shown on

the rotor or in a current brake specifications book, replace

the rotor.

C. The rotor may be resurfaced if scored or it has a small

amount of runout, provided it is within the minimum

thickness requirement.

D. After the rotor is machined, measure the thickness

again, and, if it is not within the allowable minimum limits,

discard it. NOTE: This check requires a measurement in

only one spot if both braking surfaces cleaned up 100%,

because the turning operation assures almost absolute

parallelism.

Preparing For Twin Cutters

1. Remove the boring bar and tool holder brackets.

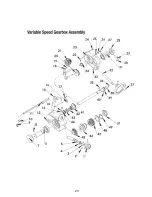

2. Using the spindle feed hand wheel, move the spindle to

its innermost (right hand) position by turning the hand

wheel clockwise and then back off by turning dial wheel

three turns counterclockwise. On some deeper rotors it

may be necessary to move the spindle farther left. For

best results, always position the spindle as far to the right

as the job will allow. NOTE: If the hand wheel does not

turn freely, check to make sure the spindle lock and trav-

el control lock knobs are loosened.

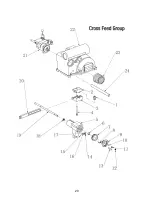

3. Turn the cross feed hand wheel counterclockwise and

move the cross feed assembly away from the arbor. This

will make room for the twin cutters after the rotor is

installed. If the hand wheel does not turn freely, check to

make sure the cross feed lock knob is loosened.

IMPORTANT NOTE

If the cross feed assembly moves too far outward the

feed screw may exit the feed screw nut and cause the

cross feed assembly to become disengaged from the

hand wheel. If this happens, simply push firmly forward

on the

RIGHT SIDE

of the cross feed assembly while at

the same time turning the cross feed hand wheel

clockwise until the feed screw engages the feed screw

nut and the cross feed assembly begins to move.

Mounting Brake Rotors

4. Clean excess grease from bearing races of rotor. Inspect

bearing races for damage and replace if necessary.

5. With the power turned off, mount the rotor on the arbor

using the proper adapters, cones, and spacers.

Hubbed Brake Rotors

Tapered centering cones or double taper adapters fit in the

bearing seats. Be sure to make contact near the middle of

the bearing race whenever possible rather than near an

edge. Various adapters and/or spacers may be used to fill

out the shaft of the arbor.

13