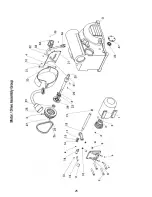

Hubless Brake Rotors

Select a hubless adapter which will fit inside the drum

against the flat surface. Be sure to remove any burrs with

sandpaper or wire brush. Slip the hubless adapter onto the

arbor followed by a spring, centering cone, the drum, and

another hubless adapter. Fill out the remaining shaft with

various adapters and/or spacers as needed.

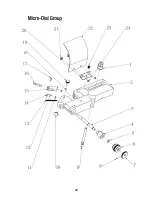

6. With the power turned off, mount the micro-dial twin

cutter assembly on the tool holder stud bolt extending the

bolt through the cast slot. The slot of the twin cutter should

be approximately parallel to the lathe spindle and the center

of the twin cutters lined up with the centerline of the rotor.

NOTE: It helps to use the safety shield mounting bolt as a

guide to line up twin cutters with the centerline of rotor.

7. Secure the twin cutter to the tool holder with the self

aligning nut and washer assembly. Tighten the nut firmly.

8. Install the safety shield if it was removed for storage

then review the cautions and dangers section and the

general safety information at the beginning of this

manual. The safety shield is easily screwed onto the twin

cutter in the threaded mounting hole provided.

IMPORTANT NOTE

:

Do not overtighten arbor nut when mounting rotors on

the spindle. The pressure of one hand on the wrench is

sufficient to tighten. If centering cones, adapters and

spacers are not clean and free of nicks and burrs or

foreign matter when the arbor is tightened, it could

introduce spindle runout or “wobble”.

9. With the power turned off, install a silencer band that is

appropriate for the rotor being machined. Stretch the band

around the rotor and hook the metal loop over a lead weight.

10. Adjust both micrometer tool-feed knobs on the tool

holders making sure the cutting bits are opened wider than

the width of the rotor.

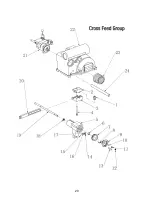

11.Turn the cross feed hand wheel clockwise and

manually feed the cutting tools inward stopping near the

center of the rotor. Remember, the hand wheel will not turn

manually unless the cross feed lock knob is loosened.

14