29

INSTALLATION

Check the appliance is electrically safe and gas sound when you have finished.

After completing the gas connection, check the

cooker is gas sound with a pressure test. When

checking for gas leaks do not use washing up

liquid - this can corrode. Use a product specifically

manufactured for leak detection.

Pressure testing

The gas pressure can be measured at one of the

centre hotplate burner injectors (not the Wok

burners). Lift off a burner head. Fit the pressure

gauge to the injector. Turn on and light one of the

other hotplate burners. Press in the control knob for

the burner with the pressure gauge fitted to let gas

through.

Pressures

Natural Gas

LP Gas cookers

20mbar.

Butane

29mbar

Propane

37mbar

Reassemble burner top, making sure it is reassembled

in the correct way on the burner body.

Electrical Connection

This appliance must be installed by a qualified

electrician to comply with the relevant Institute of

Electrical Engineers (I.E.E.) regulations and also the

local electricity supply company requirements.

WARNING: THIS APPLIANCE MUST BE EARTHED

Note

The cooker must be connected to the correct

electrical supply as stated on the voltage label on

the cooker, through a suitable cooker control unit

incorporating a double pole switch having a contact

separation of at least 3mm in all poles. This cooker

must not be connected to an ordinary domestic

power point.

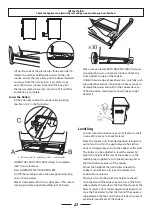

ArtNo.130-0010 Electrical connections single-phase

L

N

230 V ac 50 Hz

10mm² max

Access to the mains terminal is gained by removing

the electrical terminal cover box on the back panel.

Connect the mains cable to the correct terminals for

your electrical supply type (see fig.). Check that the

links are correctly fitted and that the terminal screws

are tight. Secure the mains cable using the cable

clamp.

These appliances are of type X with regard to

protection against over heating of the surrounding

surfaces.

Current Operated Earth Leakage Breakers

The combined use of your cooker and other domestic

appliances may cause nuisance tripping, so we

recommend that the cooker is protected on an individual

RCD (Residual Current Device) or RCBO (Residual Current

Breaker with Overload).

IF IN DOUBT, PLEASE CONSULT A SUITABLY QUALIFIED

ELECTRICIAN.

Hotplate

Check each burner in turn. There is a flame safety

device that stops the flow of gas to the burner if the

flame goes out. There is also a spark ignition system

that works when the knob is pressed in.

For each burner, push in and turn the knob to the

solid flame symbol ( ).

The igniter should spark and light the gas. Keep

holding the knob pressed in to let the gas through to

the burner for few seconds. If, when you let go of the

control knob, the burner goes out, the safety device

has not held in. Turn the control to the off position

and wait one minute, then try again this time holding

in the control knob for slightly longer.

Turn off the burners.

Oven check

Set the clock to the time of day

When the clock is first connected the display will flash

(

0.00

) and (

) alternately.

To set the clock to read the time of day turn and hold

the Timer knob to the clock symbol and at the

same time turn the Adjusting knob left or right until

the clock shows the time of day. Remember this is

a 24 hour clock. Let go of the Timer knob and it will

spring back to the vertical oven manual setting.

Turn on the oven and check that the oven fan starts

to turn and that the oven starts to heat up.

Summary of Contents for Elite SE

Page 1: ...Elite SE 110 Dual Fuel FSD Users Guide Installation Service Instructions U103980 07A...

Page 2: ...2...

Page 38: ...38...

Page 39: ...39...