QUANTECH

59

SECTION 3 - HANDLING, STORAGE, INSTALLATION, AND REASSEMBLY

FORM QWC4-NM1 (221)

ISSUE DATE: 02/28/2021

3

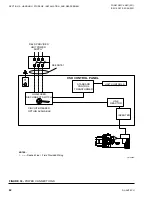

How To Receive Voltage Or Current Signal

The control board JUMPER JP4 must be positioned

correctly to receive a voltage (0-10 VDC or 2-10 VDC)

or a current (0 mA to 20 mA or 4 mA to 20 mA) signal.

Place the jumper in the

V

position for a

voltage

sig-

nal, or

mA

for a

current

signal. Configure the software

under the OPTIONS key for the specific type of input

signal to be used.

The maximum temperature reset (100%) is achieved at

either 10 VDC or 20 mA. Sending the minimum signal

(0 VDC or 2 VDC, 0 mA or 4 mA, based on the OP-

TIONS key) causes the setpoint to revert back to its lo-

cal programmed value. If the setpoint reset causes the

setpoint to go over the maximum programmable value,

it will be set to the maximum programmable setpoint.

0 VDC to 10 or 2 VDC to 10 VDC Reset Input

A 0 VDC or 2 VDC signal produces a 0°F (0°C) re-

set. A 10 VDC signal produces a 100% (max.) reset

(SETPOINTS key). The setpoint reset is ramped lin-

early between these limits as the input varies between 0

or 2

VDC and 10 VDC. For this input to work properly,

the Remote Temperature Reset must be programmed

for 0 VDC to 10 VDC or 2 VDC to 10 VDC input (OP-

TIONS key) and control board JUMPER JP4 placed in

the

V

position.

0 mA to 20 mA or 4 mA to 20 mA Reset Input

A 0 mA or 4

mA signal produces a 0°F (0°C) reset. A 20

mA signal produces 100% (max.) reset (SETPOINTS

key). The setpoint reset is ramped linearly between

these limits as the input varies between 0 mA or 4 mA

and 20 mA. In order for this input to work properly,

program the Remote Temperature Reset for 0 mA to 20

mA or 4 mA to 20 mA input (OPTIONS) and control

board JUMPER JP4 placed in the

mA

position.

Leaving Condenser Liquid Temperature Reset

Control

The same input used for Leaving Chilled Liquid Tem-

perature Reset is used for Leaving Condenser Liquid

Temperature Reset when the heat pump option is in-

stalled. The function of the input is controlled by se-

lecting the operating mode described in

in this manual.

Current Limit Reset Control

Install input for Current Limit Reset Control across

Terminals 19 (+) and 20 (-) of the 1TB Terminal Block.

How to Receive Voltage or Current Signal

The control board JUMPER JP5 must be positioned

correctly to receive a voltage (0 VDC to 10 VDC or 2

VDC to 10 VDC) or a current (0 mA to 20 mA or 4 mA

to 20 mA) signal. Place the jumper in the

V

position for

a voltage signal or

mA

for a current signal. Configure

the software under the OPTIONS key for the type of

input signal to be used.

The minimum current limit setpoint is achieved at ei-

ther 10 VDC or 20 mA. Sending the minimum signal

(0 VDC or 2 VDC, 0 mA or 4 mA, based on the OP-

TIONS key) causes the current limit to revert back to

its maximum value.

0 VDC to 10 VDC or 2 VDC to 10 VDC Reset

Input

A 0 VDC or 2 VDC signal produces a 0°F (0°C) re-

set. A 10 VDC signal produces a 100% (max.) reset

(SETPOINTS key). The setpoint reset is ramped lin-

early between these limits as the input varies between

0 VDC or 2

VDC and 10 VDC. In order for this input

to work properly, the Remote Temperature Reset must

be programmed for 0VDC to 10 VDC or 2 VDC to 10

VDC input (OPTIONS key) and control board JUMP-

ER JP5 placed in the

V

position.

0 mA to 20 mA or 4 mA to 20 mA Reset Input

A 0 mA or 4

mA signal produces a 0°F (0°C) reset. A 20

mA signal produces 100% (max.) reset (SETPOINTS

key). The setpoint reset is ramped linearly between

these limits as the input varies between 0 mA or 4 mA

and 20 mA. In order for this input to work properly,

the program the Remote Temperature Reset for 0 mA

to 20 mA or 4 mA to 20 mA input (OPTIONS key) and

control board JUMPER JP5 placed in the

mA

position.

INSTALLATION CHECKLIST – REQUEST FOR

START-UP SERVICE

When all items on the

Installation Checklist and

Request for Authorized Start-up Technician

(Form

QWC4-CL1)

(North America Only)

are completed

satisfactorily, and before any attempt is made to start

the unit, contact the Quantech Field Service Office to

schedule the start-up service.

Summary of Contents for QWC4

Page 14: ...QUANTECH 14 FORM QWC4 NM1 221 ISSUE DATE 02 28 2021 THIS PAGE IS INTENTIONALLY LEFT BLANK...

Page 64: ...QUANTECH 64 FORM QWC4 NM1 221 ISSUE DATE 02 28 2021 THIS PAGE IS INTENTIONALLY LEFT BLANK...

Page 82: ...QUANTECH 82 FORM QWC4 NM1 221 ISSUE DATE 02 28 2021 THIS PAGE IS INTENTIONALLY LEFT BLANK...

Page 130: ...QUANTECH 130 FORM QWC4 NM1 221 ISSUE DATE 02 28 2021 THIS PAGE IS INTENTIONALLY LEFT BLANK...

Page 146: ...QUANTECH 146 FORM QWC4 NM1 221 ISSUE DATE 02 28 2021 THIS PAGE IS INTENTIONALLY LEFT BLANK...

Page 152: ...QUANTECH 152 FORM QWC4 NM1 221 ISSUE DATE 02 28 2021 THIS PAGE IS INTENTIONALLY LEFT BLANK...

Page 155: ...QUANTECH 155 NOTES...