October 2003

Page 16–9

Chapter 16. Universal Checkback Module

16

Step 1. Unpack the module.

||Open the carton and remove the Universal

Checkback Module. Check the software versions

of all checkback modules working together to

make sure they are the same basic revision, espe-

cially if they were shipped from Pulsar at different

times. Revision 1.0x will not work with revision

2.0x, for example. For optimum operation all

modules should be the same revision. Check

Pulsar's website for PLC software downloads to

upgrade to the latest revision. You can check the

version by looking at the label on the programmed

chip (U4) on the Universal Checkback module. If

this is missing then you will need to connect a

computer to the 9-pin serial connector on the front

of the module and power it up. Refer to Fig. 16-4.

Before operating the Universal Checkback

modules, verify that manual keying (using the HL

& LL pushbuttons on front of the Keying module)

of both transmitters gives a correct response at the

corresponding far end receiver. LL (low level)

keying should give -10 dB on both the local and

far end Receiver module. HL (high level) keying

should give 0 dB on both the local and far end

receiver module. NOTE: The self-adjusting

receiver has two sensitivity settings that need to be

made. The first one is for setting with the far end

transmitter keyed to 10W (HL) and the second

sensitivity (local) setting is for the local trans-

mitter keyed to 10W (HL).

For a 3-terminal line you have to set each receiver

module to the weakest transmitter signal coming

in. Only for the weakest remote transmitter and for

your local transmitter will you see 0 dB for HL

keying and -10 dB for LL keying. Other transmit-

ters will have a higher signal level (shown on the

Receiver module).

For installations where you have not already tried

known settings it is recommended you first try

Pulsar's standard factory settings regardless of

your final desired settings. This allows you to

know that at least the system works with standard

factory settings, and then you can check for incon-

sistencies in your settings if your settings don't

work and the standard factory settings do.

For 2-terminal lines set the Universal Checkback

module that you want to be the master to Factory

Setting # 1 by setting the 4 position DIP switch

(S1) to have position 1 down (ON) and all other

three positions up (OFF). Note that the green LED

#1 will come on when it is set to factory setting #1.

Then set the other Universal Checkback module

that you want to be the remote to Factory Setting

# 2 by setting the 4 position DIP switch (S1) to

have position 2 down (ON) and all other three

positions up (OFF). Note that the green LED #2

will come on when it is set to factory setting

#2.These particular factory settings should give

you a green "CHECK OK" LED after performing

a checkback test. Then you can you change the

settings to whatever you desire and try again.

For 3-terminal lines you can do something similar

as for 2-terminal lines above. Set the master to

Factory Setting # 1 and the first & second remotes

to Factory Setting # 2. Then using a computer

change the master, first remote, and second remote

settings to say "Last Remote = 2" by typing "set

last 2", and in addition change the second remote

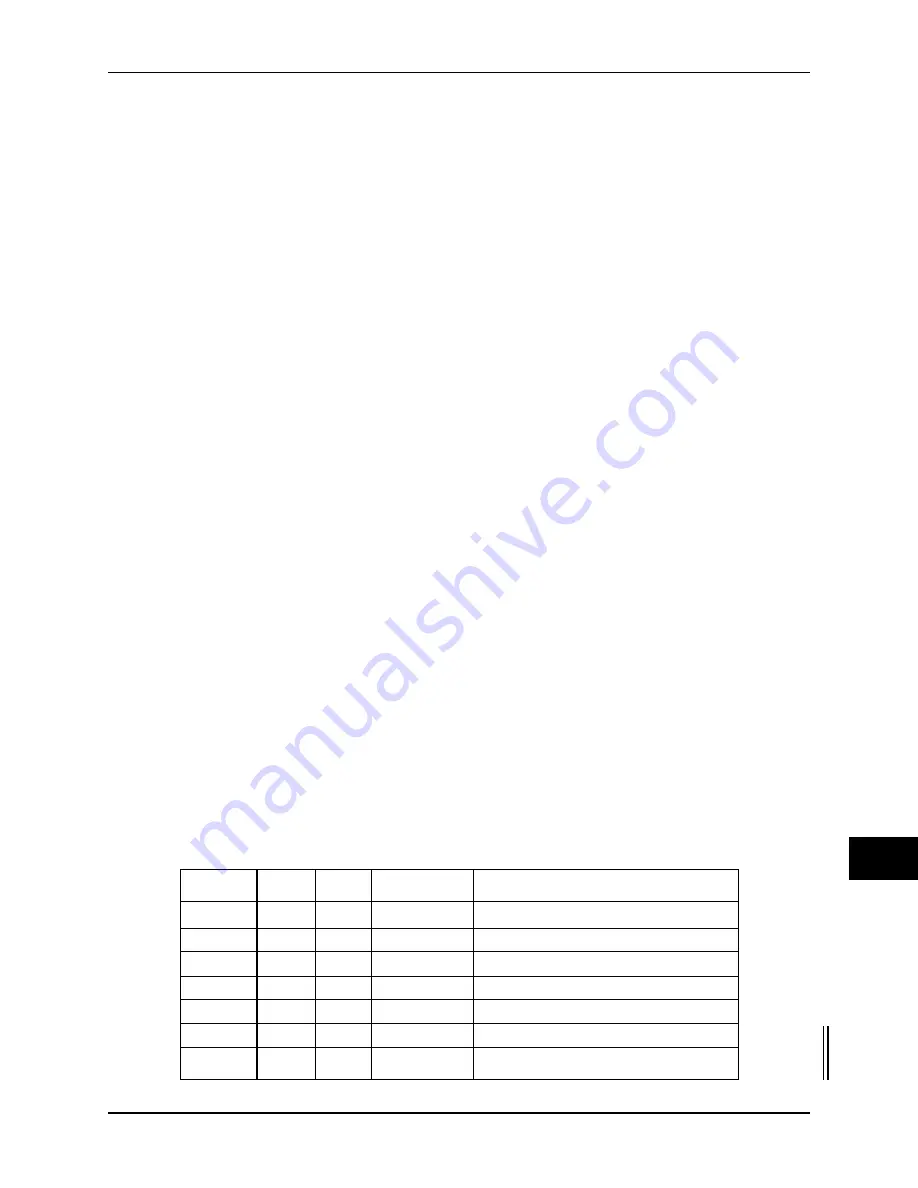

Table 16–2. Universal Checkback Module DIP Switch Settings.

S1

S2

S3

S4

Settings Option

off

off

off

not used

Custom Settings Enabled

on

off

off

not used

Factory Preset #1 Settings

off

on

off

not used

Factory Preset #2 Settings

on

on

off

not used

Factory Preset #3 Settings

off

off

on

not used

Factory Preset #4 Settings

on

off

on

not used

Factory Preset #5 Settings

off

on

on

not used

Factory Preset #6 Settings

Summary of Contents for TC-10B

Page 2: ...Technologies Inc...

Page 12: ...Technologies Inc...

Page 22: ...Page 1 10 October 2003 TC 10B System Manual Technologies Inc Technologies Inc USER NOTES...

Page 44: ...Page 2 22 October 2003 TC 10B System Manual Technologies Inc Technologies Inc USER NOTES...

Page 53: ...3 Figure 3 3 TC 10B Mechanical Outline Drawing 1354D48...

Page 56: ...Page 3 12 October 2003 TC 10B System Manual Technologies Inc Technologies Inc USER NOTES...

Page 58: ...Page 4 2 October 2003 TC 10B System Manual Technologies Inc Figure 4 1 Extender Board...

Page 90: ...Figure 9 2 TC 10B TCF 10B Power Supply Component Location 1617C38...

Page 91: ...9 Figure 9 3 TC 10B TCF 10B Power Supply Schematic 1617C39...

Page 92: ...Page 9 6 October 2003 TC 10B System Manual Technologies Inc Technologies Inc USER NOTES...

Page 97: ...10 Figure 10 2 TC 10B Keying PC Board 1495B69...

Page 98: ...Figure 10 3 TC 10B Keying Schematic 1606C29...

Page 104: ...Figure 11 3 TC 10B TCF 10B Transmitter PC Board 1500B10...

Page 106: ...Figure 11 5 TC 10B Transmitter Block Diagram 1610C09...

Page 107: ...11 Figure 11 6 TC 10B Optional TTL Transmitter Component layout CC20 TXMA1 001...

Page 112: ...Figure 12 2 TC 10B TCF 10B 10W PA PC Board 1495B73...

Page 113: ...12 Figure 12 3 10W PA Schematic 1606C33...

Page 114: ...Page 12 6 October 2003 TC 10B System Manual Technologies Inc Technologies Inc USER NOTES...

Page 117: ...13 Figure 13 2 TC 10B TCF 10B RF Interface PC Board 1609C32...

Page 118: ...Figure 13 3 TC 10B TCF 10B RF Interface Schematic 1609C32 2...

Page 126: ...Page 14 8 October 2003 TC 10B System Manual Technologies Inc Technologies Inc USER NOTES...

Page 132: ...Figure 15 3 TC 10B Receiver Output PC Board CC50RXSM...

Page 133: ...15 Figure 15 4 TC 10B Receiver Output Schematic CC30RXSM...

Page 134: ...Page 15 8 October 2003 TC 10B System Manual Technologies Inc Technologies Inc USER NOTES...

Page 178: ...Page 16 44 October 2003 TC 10B System Manual Technologies Inc Technologies Inc USER NOTES...

Page 184: ...Figure 17 3 Voice Adapter Module PC Board C020VADMN...

Page 189: ......

Page 190: ...Technologies Inc...