● Nozzle temperature:

270 - 280 °C

● Bed temperature:

100 - 110 °C (bigger object -> higher temp.)

● Heatbed:

Make sure the surface of the heatbed is clean. Usage of brim is suggested

(see Prusa Knowledgebase).

11.10 nGen

Developed by Eastman Chemical Company and colorFabb, nGen offers increased

resistance to heat as well as dimensional stability. The material is low-odor and styrene-free.

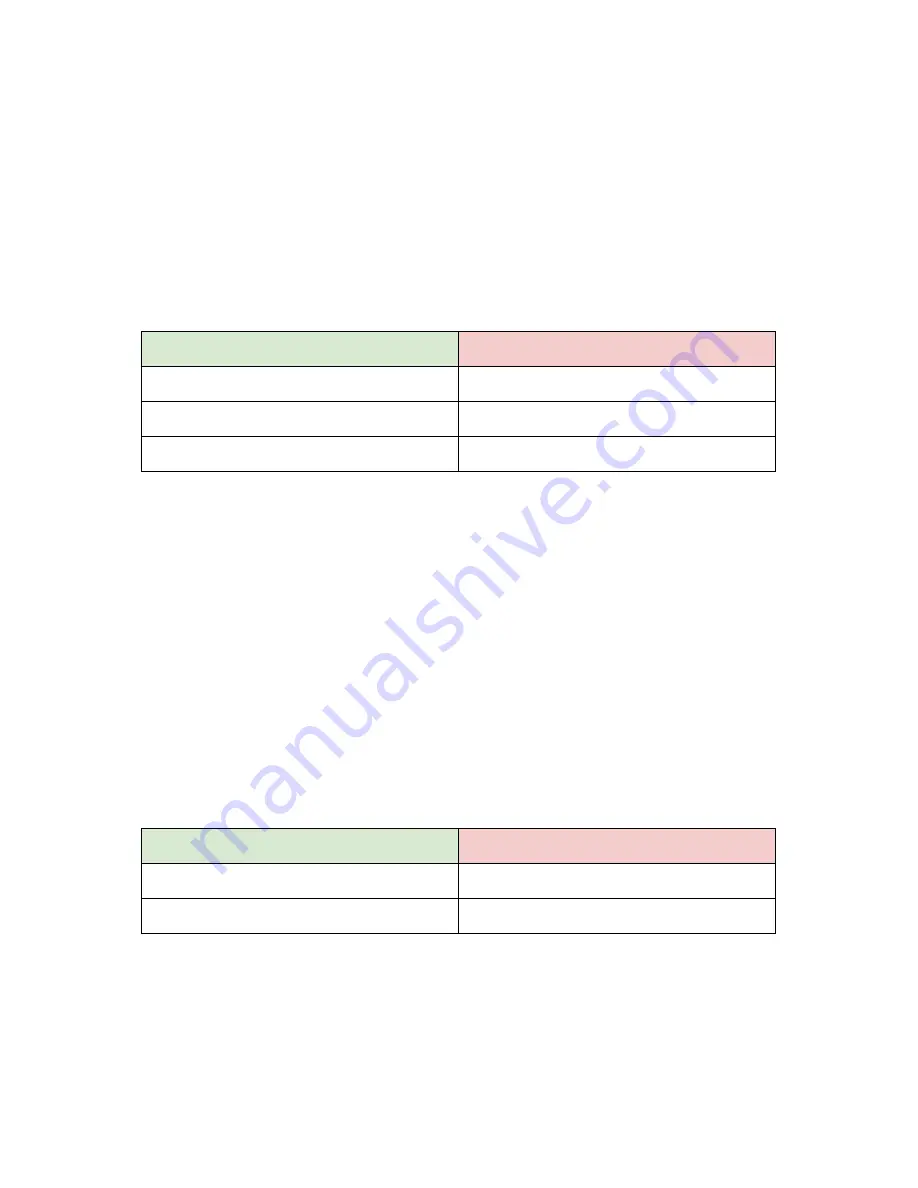

ADVANTAGES

DISADVANTAGES

High gloss

Brittle

Good surface finish

A bit of warping

Good layer adhesion

● Nozzle temperature:

240 °C

● Bed temperature:

80 - 100 °C (bigger object -> higher temp.)

● Heatbed:

Make sure the surface is clean. Do not use isopropyl alcohol to clean the

bed, otherwise the adhesion may be too strong, use window cleaner instead. If you

do not have anything else on hand, use the bundled glue as a separator after

cleaning it. Windex or similar window cleaner is a great option for nGen and you don’t

need to use the glue after the cleaning. Spray a small amount on an unscented paper

towel, and wipe the print surface.

11.11 PC-ABS (E3D)

Polycarbonate ABS (PC-ABS) is an enhanced version of traditional ABS. It offers easier

processing, higher strength, stiffness, and temperature resistance. PC-ABS is also suitable

for structures with openings and its bridging capability is improved compared to ABS. Typical

usage of PC-ABS is for durable plastic parts like television or computer casings.

ADVANTAGES

DISADVANTAGES

Lightweight

Warps

Good for mechanical parts

Low elasticity

● Nozzle temperature:

270 - 280 °C

● Bed temperature:

100 - 110 °C (bigger object -> higher temp.)

● Heatbed:

Make sure the surface of the heatbed is clean.

56

Summary of Contents for i3 MK2.5

Page 1: ......

Page 64: ...Pict 40 Nozzle change 64 ...