SECTION 5

PUV-3600HD / PUV-4000HD

5.21

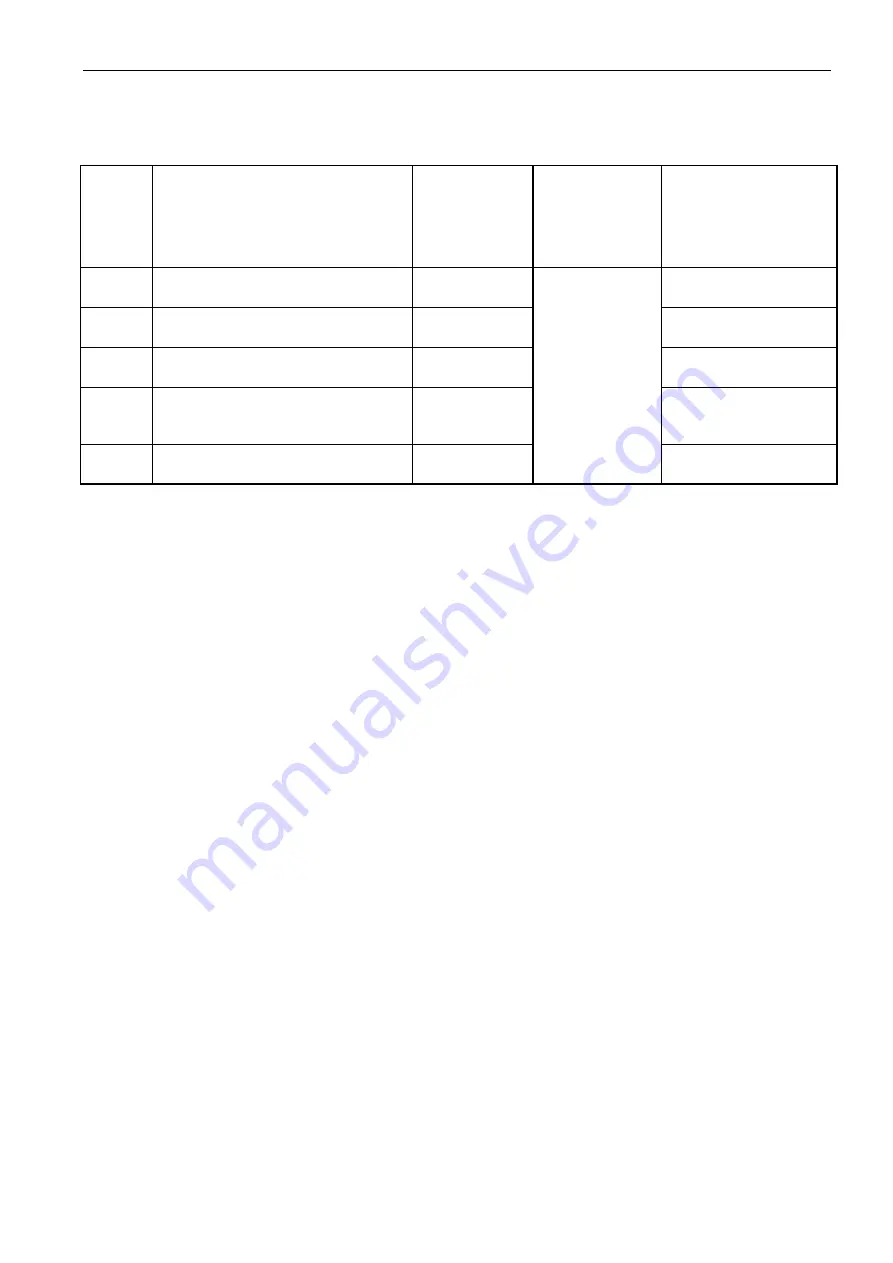

TABLE 5.17

LUBRICATION POINTS AND LUBRICATION FREQUENCY

ITEM

NAME

NUMBER

OF

LUBRICATI

ON POINTS

TYPE OF

GREASE

LUBRICATION

FREQUENCY

A

Blade main pivot pin

4

50 hours

B

Linkage skid plate

2

20 hours

C

Linkage head plate

2

20 hours

D

Height adjustment bolt and

wheel column

1+1

20 hours

E

Hydraulic cylinder eye

2+2

grease

50 hours

Marking description in Item column TABLE 5.17 conforms with numbering shown FIGURE 5.14

5.8

STORAGE

After finishing work, the machine should be thoroughly cleaned and washed with a water jet.

While washing, do not direct a strong water or steam jet at information and warning decals or

hydraulic conduits and electrical components. Nozzle of pressure or steam washer should be

kept at a distance of not less than 30 cm from cleaned surface.

After cleaning, inspect the whole machine, inspect technical condition of individual elements.

Used or damaged elements should be repaired or replaced.

In the event of damage to the paint coat, clean rust and dust from damaged area, degrease

and then paint with undercoat and after it is dry paint with surface coat paint retaining colour

uniformity and even thickness of protective coating. Until the time of touch-up painting, the

damaged place may be covered with a thin layer of grease or anticorrosion preparation.

Machine should be kept in closed or roofed building.

If the machine shall not be used for a long period of time, protect it against adverse weather

conditions. Lubricate machine according to the instructions provided. In the event of a

prolonged work stoppage, it is essential to lubricate all components regardless of the date of

the last lubrication. Additionally, before winter, apply grease to hitching system pins.

Machine disconnected from the carrying vehicle should be placed on parking stands, on

level, sufficiently hard surface in such a manner as to ensure that it is possible to connect it

again.

Summary of Contents for PUV-3600HD

Page 2: ......

Page 3: ...SNOW PLOUGH PRONAR PUV 3600HD PRONAR PUV 4000HD MACHINE IDENTIFICATION TYPE SERIAL NUMBER ...

Page 6: ......

Page 9: ...SECTION 1 BASIC INFORMATION ...

Page 19: ...SECTION 2 SAFETY ADVICE ...

Page 29: ...SECTION 3 DESIGN AND OPERATION ...

Page 38: ...PUV 3600HD PUV 4000HD SECTION 3 3 10 ...

Page 39: ...SECTION 4 CORRECT USE ...

Page 58: ...PUV 3600HD PUV 4000HD SECTION 4 4 20 ...

Page 59: ...SECTION 5 MAINTENANCE ...

Page 82: ...PUV 3600HD PUV 4000HD SECTION 5 5 24 ...

Page 83: ...NOTES ...