19

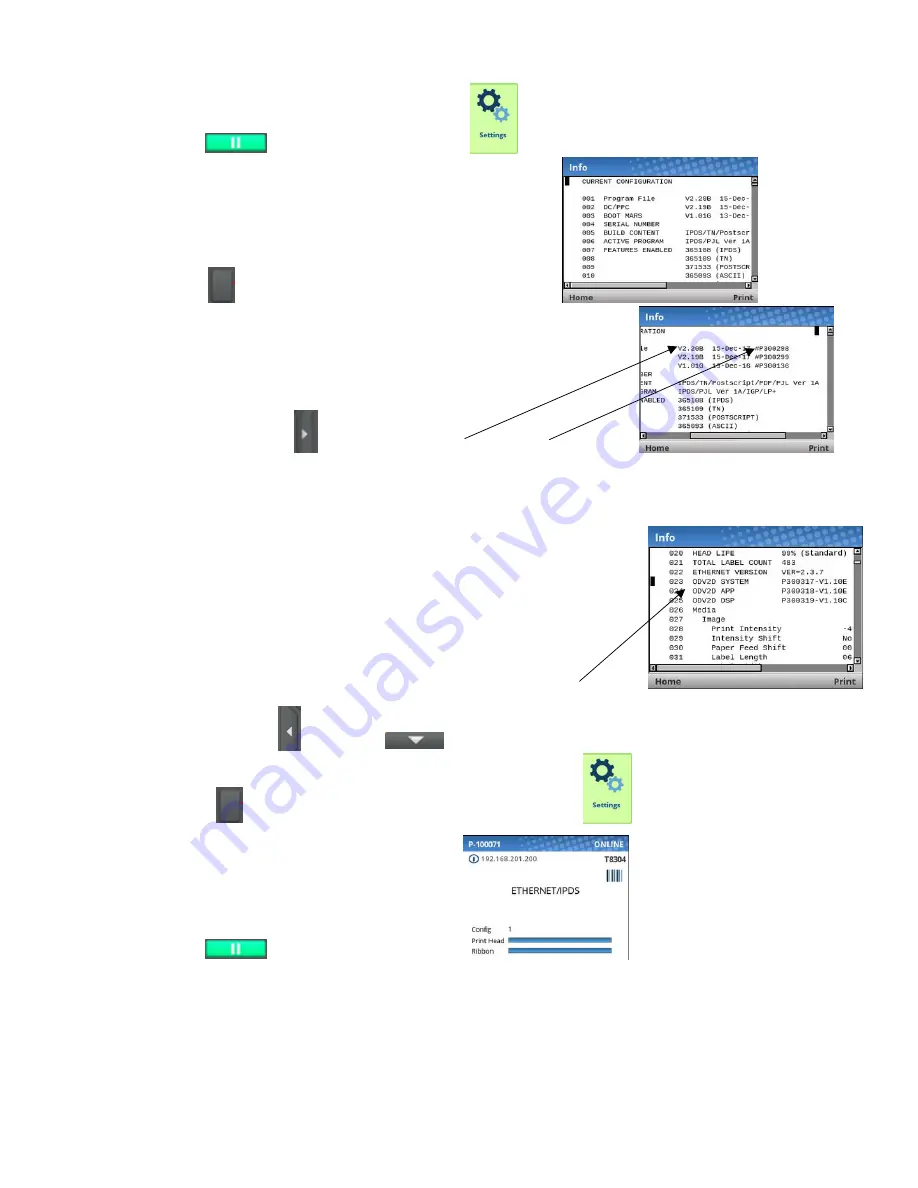

View Printer Software Version

1. Press PAUSE

key to take printer OFF-LINE

.

2. Press the right

Soft Key #2 Cancel / Back, panel should display

.

3. Press the RIGHT ARROW

until Program File version and Part No. appear

.

View ODV2D-V2 System / APP / DSP

1. Press the LEFT ARROW

and DOWN

keys until control panel displays ODV2D-V2 system

2. Press the LEFT

Soft Key #1 Menu / Home to return to home menu

.

3. Press PAUSE

key to take printer ON-LINE

.

4. Contact Printronix Auto ID for the latest Printer and ODV2D-V2 software versions needed for best performance.

Refer to the T8000 Admin

istrator’s

Manual for software download instructions.

Verifying T8 Printhead Element Functionality

IMPORTANT All T8 printhead elements must be functioning in order to support the ODV2D-V2 validator.