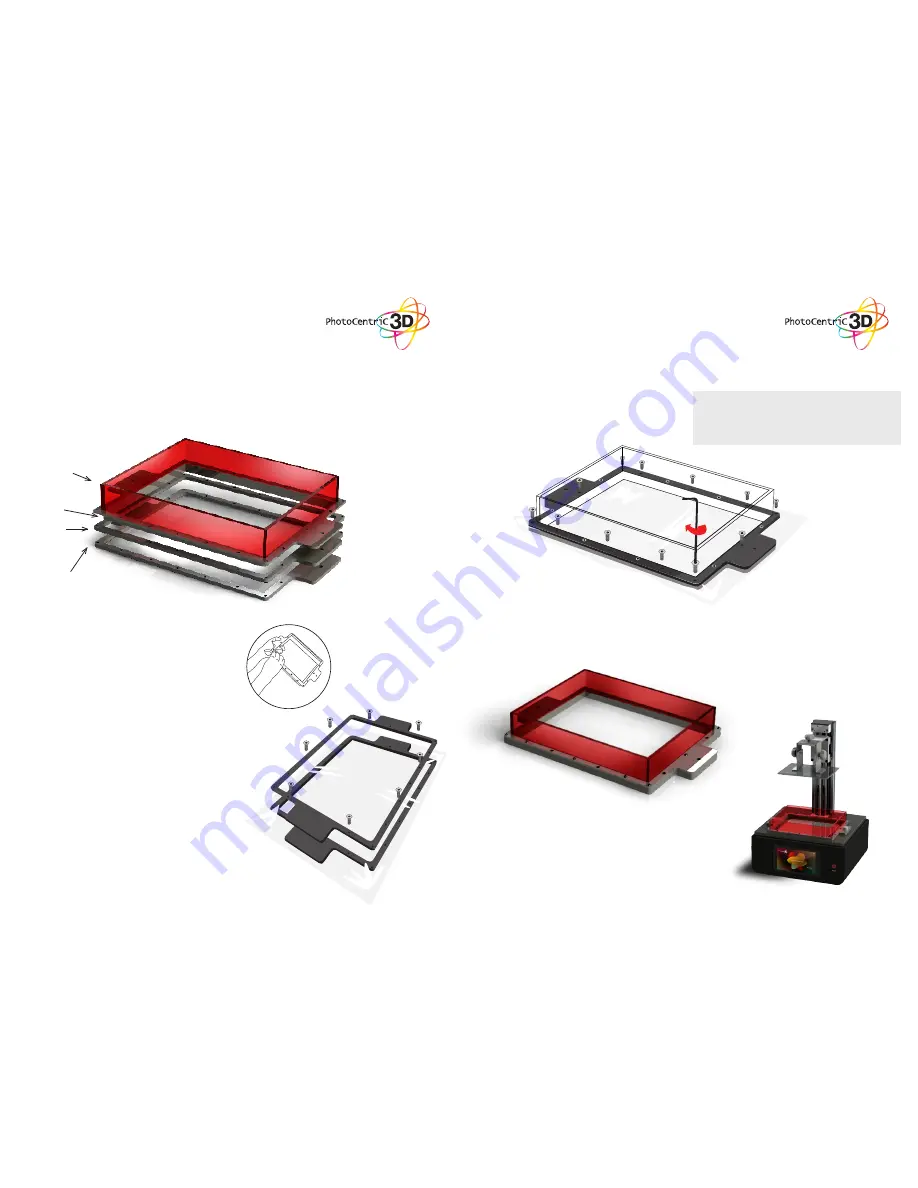

1.

Remove all the retaining bolts from the vat.

2.

Dispose of the vat film. Wipe the vat clean and

wash all parts with soap and water.

3.

Place the “Vat Base Flange D flat on a table”

with the brass inserts pointing down.

4.

Check the new vat film isn’t pierced or dented

and lay it on top of the “Vat Base Flange D”.

5.

Place the “Vat Retaining Flange C” on top of the

film, aligning the holes with the corresponding

ones on the “Base Flange D”.

6.

Loosely insert the 8 x M3 8mm bolts as shown.

7. RE-SKINNING

THE VAT

VAT Tensioning

Ring -

B

VAT Top

Flange -

A

Retaining

Flange -

C

Metal

Retaining

Base Flange -

D

7.

Place the main vat tray over the film and gently

press down. Screw the four corners first loosley.

Tighten the M3 bolts which were inserted in

step 6. Tighten the four corner bolts, insert and

tighten the remaining bolts.

Note: Do not fully tighten each bolt individually.

This will cause the Main Vat to tension at an

angle. Aim to half tighten the bolts and fully

tighten once all the bolts are secured.

8.

The vat should now be tensioned. Trim excess edges off the film.

9.

Fill with water and leave on absorbent paper to check for leaks. Drain and dry with paper towel

before use.

13

14

Important:

Clean all the

parts before

reassembly