3

. After all the liquid resin has drained off, gently

remove any excess polymer with absorbent

paper. The fastest way to clean it and achieve

a dry surface is by spraying or immersing it in

IPA. Alternatively you can wash it in hot water

and detergent. Hold the part under running hot

water and gently clean it with a soft brush or

sponge and liquid detergent. Then remove the

object by sliding a scraper in at the base and

cut off the supports. Take care not to damage

it, it will not achieve full hardness until after

post exposing in light. An ultrasonic cleaner is

useful to clean delicate objects.

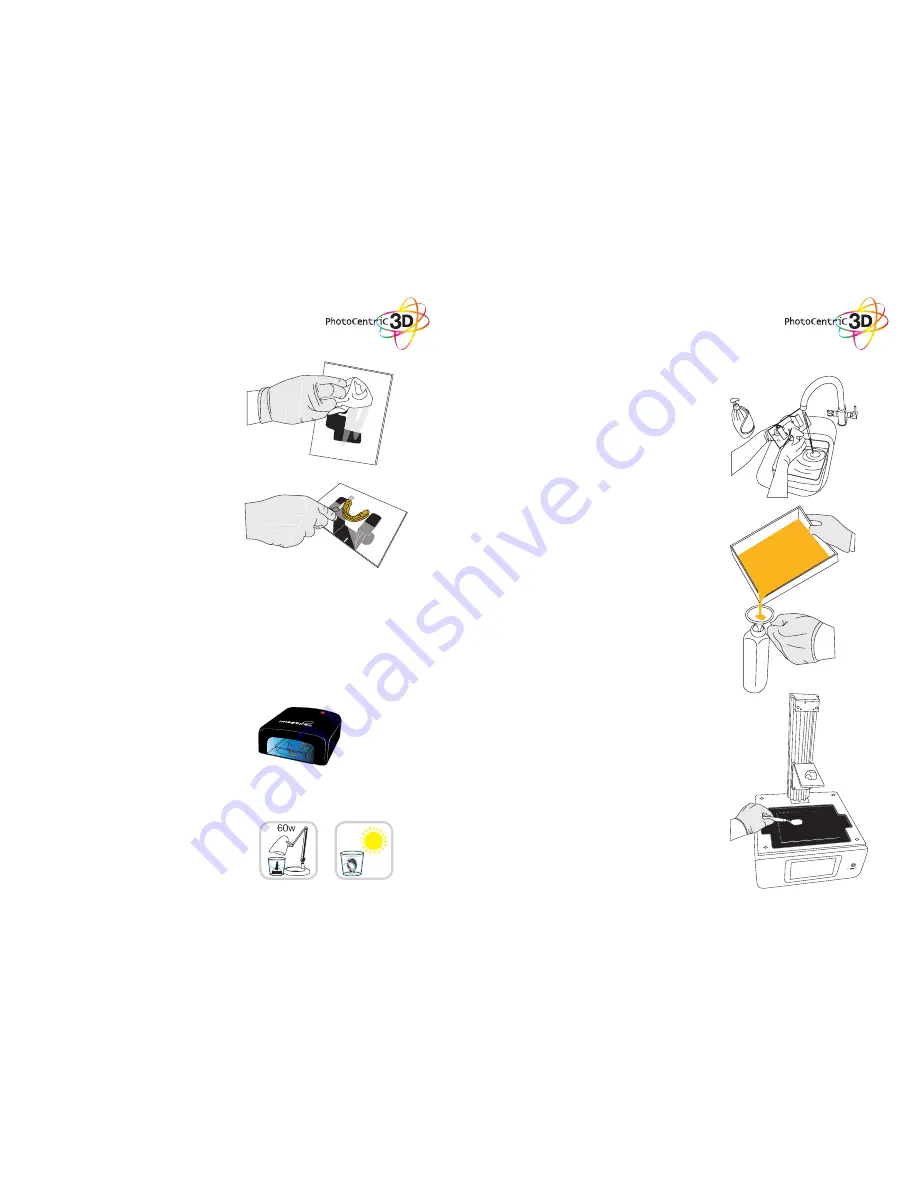

1.

When completely clean, place it underwater in

light (UV, sunlight or a table light) for a least 30

minutes to remove the surface tack. The part

will only have around 1/4 of its final strength

before post-exposure and strength increases

slowly with more light. Full strength is achieved

with 30 mins in a UV unit, or 60 mins under a

normal 60W table lamp. Then remove from

water and dry.

30 mins

post exposure

5. HARDENING

3.

If you have a leak on the screen mop up the

liquid resin immediately using absorbent paper.

Clean off with a damp cloth with detergent.

Hardened resin can be removed by chipping

off with a credit card or plastic scrapper. Metal

scrapers should only be used with extreme

care to avoid scratching the screen.

1.

Chip off any cured resin and clean the build

platform with hot water and liquid detergent.

Dry it thoroughly before inserting it back into

the printer.

2.

Empty the vat and clean it after every print in

case you have any solid pieces on the bottom

as these would prevent the platform from

homing correctly. Lift the vat from the printer;

pour the resin back into the bottle through the

filter paper into the funnel provided.

6. PREPARING FOR

THE NEXT PRINT

11

12

60 mins

post exposure

60 mins

post exposure