16

4.4. Gas Type Dependent Operations

Water cooling is required if the pumps are to be

operated with gas load.

Where high level gas loads and rotation speeds are involved,

the resulting friction subjects the rotor to the effect of great

heat. To avoid over-heating, a power rotation speed

characteristic line is implemented in the TC 600; this ensures

that where maximum gas loads are involved, the pump will

operate at any rotation speed without the danger of damage

arising.

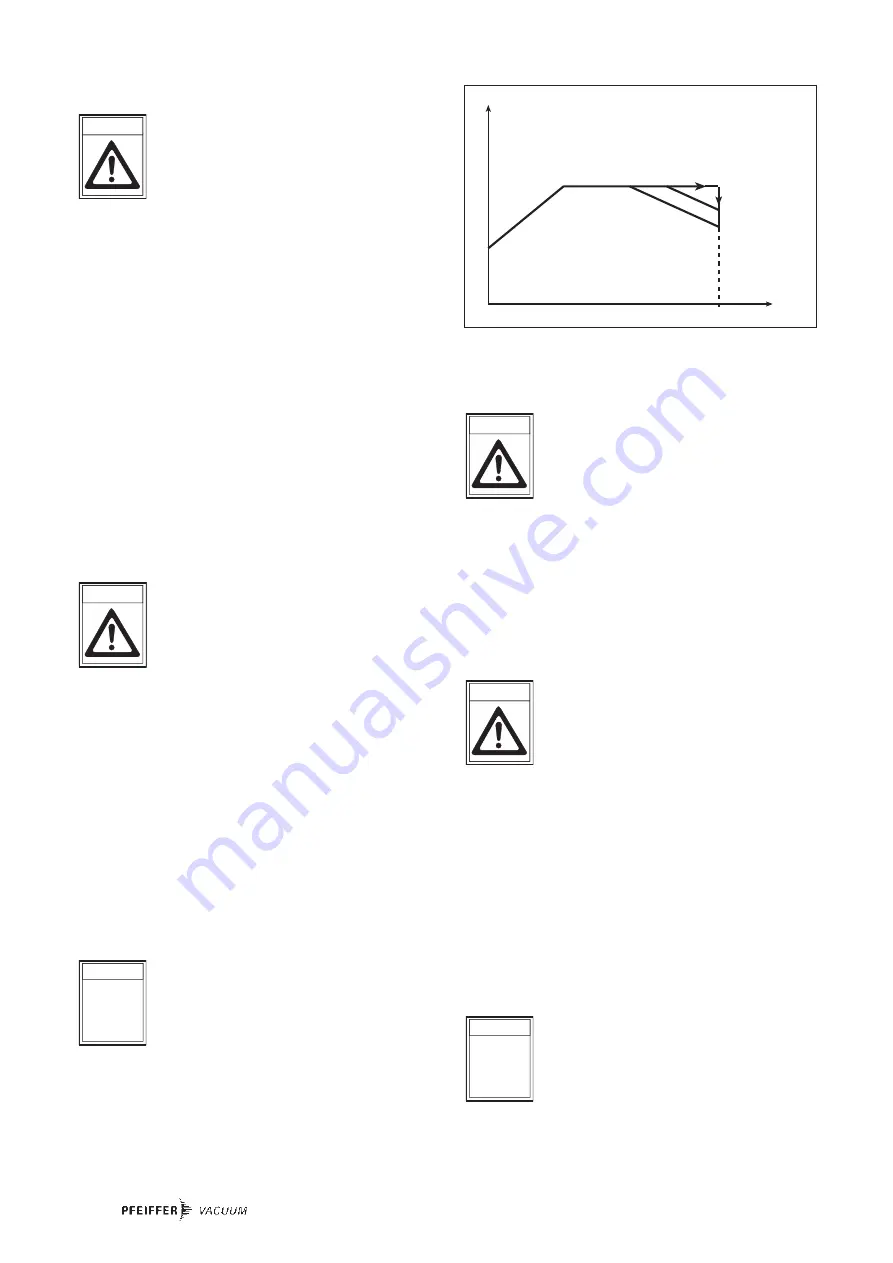

The maximum power is dependent on the type of gas. Two

characteristic lines are available for any type of gas in order

to fully exploit the power potential of the pump:

– "Gas-Mode 0" for gases with molecular mass

≥

40 as, for

example, Argon;

– "Gas-Mode 1" for all lighter gases.

Works setting: “Gas mode 0”

➡

Set the applicable gas mode on the TC 600 via the

DCU/HPU (please refer to the respective operating instruc-

tions.

Pumping gases with molecular mass

≥

40 with

the incorrect gas mode can cause damage to

the pump.When pumping noble gases heavier

then Argon it can come to the destruction of the

pump. Please contact the manufacturer before

using such gases.

For the vertex of the power characteristic line please refer to

Section 9. Technical Data.

Maximum power is applied when the pump starts in order to

limit the time required. Once the set rotation speed is

attained, switching to the selected power characteristic line

is automatic. If the gas dependent maximum power is excee-

ded, the rotation speed is reduced until equilibrium between

the permissible power and gas friction is attained.

The power limitation serves to protect the pump against ther-

mal over-loading. In order to avoid rotation speed fluctuations

it is recommended to set, in rotation speed setting mode, the

equilibrium frequency or a somewhat lower frequency.

There can be types of pump whereby there is no

differentiation between the two ”gas modes”

settings.

☞

PLEASE NOTE

WARNING

CAUTION

4.5. Shutting Down For Longer Periods

If aggressive or hazardous gases are pumped

there is a danger of personal injury resulting

from coming into contact with process gases.

Before removing a turbopump from the system,

first:

–

Vent the turbopump with a neutral gas or

dry air.

– Ensure that there is no residual process gas in the system

nor in the feeder lines.

If the turbopump is to be shut down for more than a year:

➡

Remove turbopump from the system.

➡

Change the lubricant reservoir (see Section 7.1.).

Lubricant TL 011 should not be used when there

have been no operations for 33 yye

ea

arrss..

➡

Close the high vacuum flange and evacuate the turbopump

via the fore-vacuum flange.

➡

Vent turbopump via the venting connection with nitrogen

or dry air.

➡

Close fore-vacuum and venting connection by blank

flanging.

➡

Place the pump vertically on its rubber feet.

➡

The pump must be stored in buildings within a temperature

range of -25 °C to +55 °C.

➡

In rooms with moist or aggressive atmospheres, the turbo-

pump must be air-sealed in a plastic bag together with a

bag of dessicant, e.g silicagel.

If the pump has been shut down for

3 years

, the bearing must be changed (please

contact Pfeiffer Vacuum Service).

☞

PLEASE NOTE

CAUTION

WARNING

Power

Frequency

D

B

C

A

D-C = Gas mode «0»

B-A = Gas mode «1»

Run up

fnom

Gas type characteristic line