9

C

Coonnnneeccttiioonn nnoom

miinnaall-- D

De

essiig

gn

na

attiio

on

n

O

Orrd

de

err--n

nu

um

mb

be

err

d

diia

am

me

ette

err

DN 100 CF-F

Hexagon screw M8 with

PF 505 003 -T

DN 160 CF-F

washer and nut

(25 pieces)1)

Stud screw M8 with

washer and nut

(22 pieces)1)

PF 507 003 -T

DN 100 CF-F

Copper seal (10 pieces)1)

PF 501 410 -T

or

copper seal silvered

PF 501 510 -T

(10 pieces)1)

Splinter shield2)

PM 016 315

Protective mesh2)

PM 016 336

DN 160 CF-F

Copper seal (10 pieces)1)

PF 501 416 -T

oder

copper seal silvered

PF 501 516 -T

(10 pieces)1)

Splinter shield2)

PM 016 318

Protective mesh2)

PM 016 339

The components for installing to an CF-F flange are to be

ordered under the following numbers:

1) supplied pieces

2) Insert the splinter shield and protective mesh in the high vacuum flange with the clamping lugs

downward.

The maximum loading capacity of the high

vacuum flange is 1000 N (equivalent to 100 kg).

Assymetric loading on the high vacuum flange

must be avoided.

CAUTION

No forces from the piping system must be

allowed to act on the pump where turbopumps

are anchored.

Suspend or support all pipes to the turbopump.

CAUTION

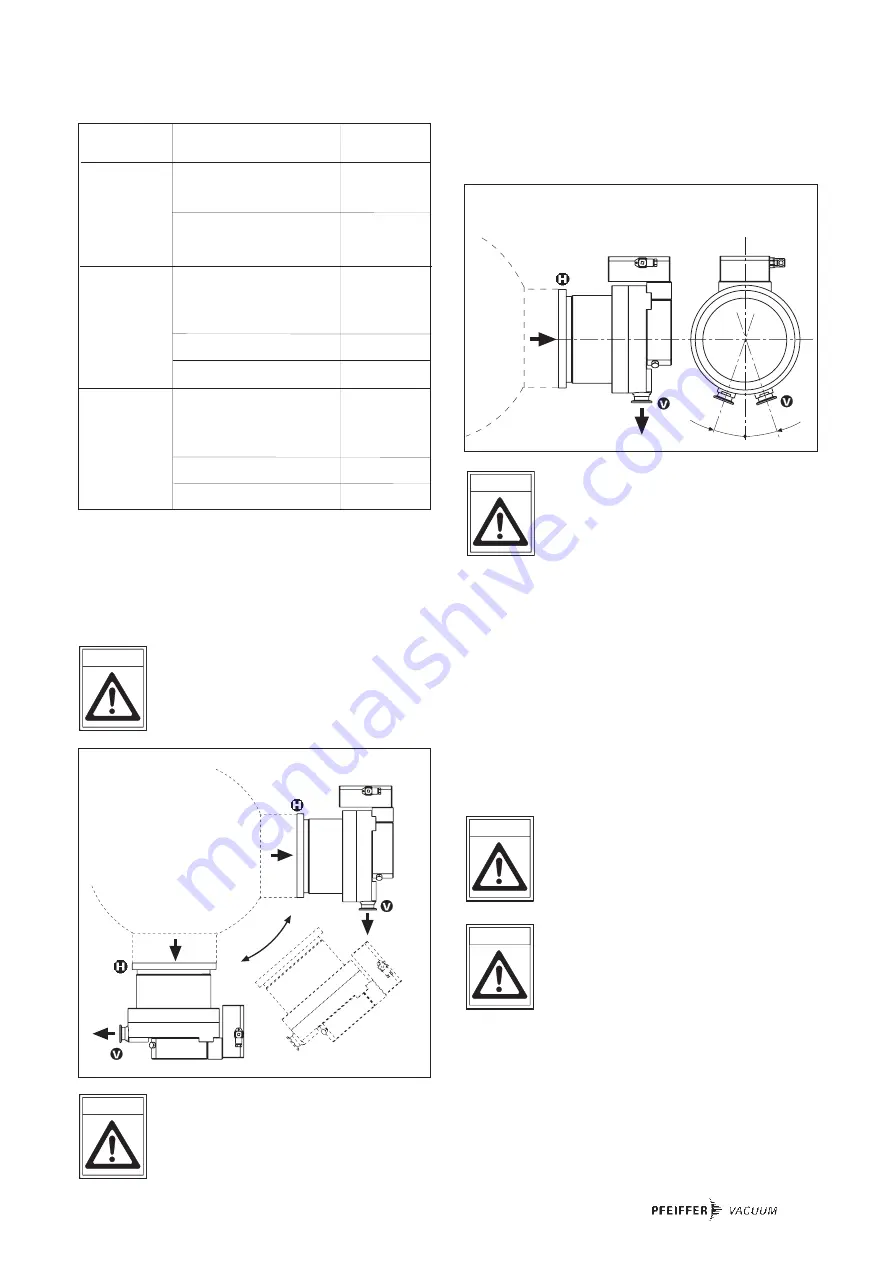

Directly flanging the pump

The turbopump can be flanged onto the vacuum chamber

vertically (0°) up to an angle of 90° maximum.

The fore-vacuum flange must always point

downwards.

CAUTION

Permissible installation positions for the turbopump

11

Vacuum chamber

20° 20°

Installation position with oil-sealed backing pump

11

Vacuum chamber

11

11

If the pump is being installed horizontally:

The fore-vacuum flange of the turbopump must be aligned

vertically downwards (maximum deviation ± 20°),

otherwise the turbopump could become dirty and the lubrica-

ting pump not properly function.

3.3. Connecting The Fore-Vacuum Side

Backing pump:

Vacuum pressure

≤

5 mbar

Recommendation:

Oil-Free Diaphragm Pump or Rotary

Vane Vacuum Pumps from the Pfeiffer

Vacuum range (note installation position,

turbopump, see Section 3.2.).

Connecting the backing pump

All connections of the fore-vacuum line: with the usual small

flange components or hose screw connections.

Be sure to conduct away the exhaust gases

from the backing pump. Do not reduce the free

cross section of the fore-vacuum flange with

following components.

The exhausted process gases and vapours can

represent a health hazard and can also be

environmentally damaging.

Comply with all gas manufacture's safety

instructions.

➡

With rigid pipe connections: fit a bellows in the connecting

line to reduce vibration.

➡

The electrical connection of the backing pump is made via

a relay box whose control line is connected to ”FV PUMP”

on the TC 600.

Please refer to Operating Instructions PT 0030 BN for details

on the relay box, backing pump and its installation.

WARNING

CAUTION