Assembly and Operation Manual

22

7.2 Operation safety requirements

General safety rules must be observed prior to operating the speed gate.

Do not!

•

Operate the speed gate in conditions that do not meet the requirements of the section 2.

•

Do not operate the speed gate at a voltage different from that is specified in the

section 3.

Power supply units should be used in accordance with the safety precautions given in their

operational documentation.

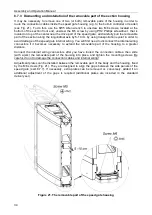

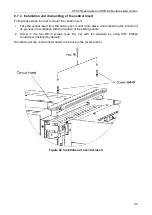

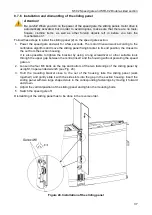

8 INSTALLATION

Speed gate installation should be performed with the observance of safety rules described in

Sect. 7.1.

Installation of the speed gate is a responsible mission, which largely defines the performance and

service life of the product. Installation must be carried out by at least four people, of which at least

two must have the qualifications of an installer and an electrician. You should carefully study this

section and follow the instructions before starting the installation procedure.

Attention!

The speed gate is a complex technical device,

perform the installation operations by

constantly following the instructions described in the section8.4

, thus you do not have

to repeat them again.

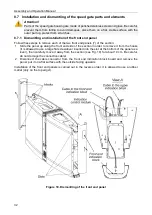

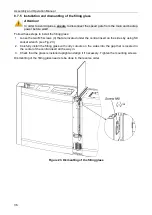

8.1 Installation details

Recommendations for the mounting surface preparations:

•

It is obligatory to mount speed gate sections on solid and even concrete (not below 400

grade, strength class B22,5), stone, etc. surfaces that have a thickness of more than 150

mm.

•

The mounting surface must be evened so that all mounting points of the speed gate section

lie in the same horizontal plane (check it with level).

•

When installing the speed gate section on a less solid foundation, it is necessary to use

reinforcing elements with a size of at least 450×450×200 mm.

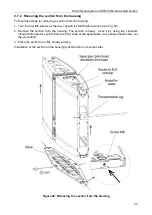

8.2 Tools and equipment required for installation

It is recommended to use the following tools and equipment for the speed gate installation:

•

two crowbars (or pipe section with a diameter up to 28 mm) to move the sections of the

speed gate;

•

1.2

÷

1.5 kW electric drill;

•

Ø16 mm carbide drill for anchor sleeves;

•

Slitting tool for the cable channels;

•

flat head screwdriver;

•

PH1, PH2 Phillips head screwdrivers;

•

S8, S13 open end wrench;

•

SW3, SW4, SW5, SW8 Allen wrenches;

•

rubber mallet;

•

level;

•

roulette 2 m.

Note:

It is allowed to use other equipment and measuring tools that meet the required parameters.