Assembly and Operation Manual

40

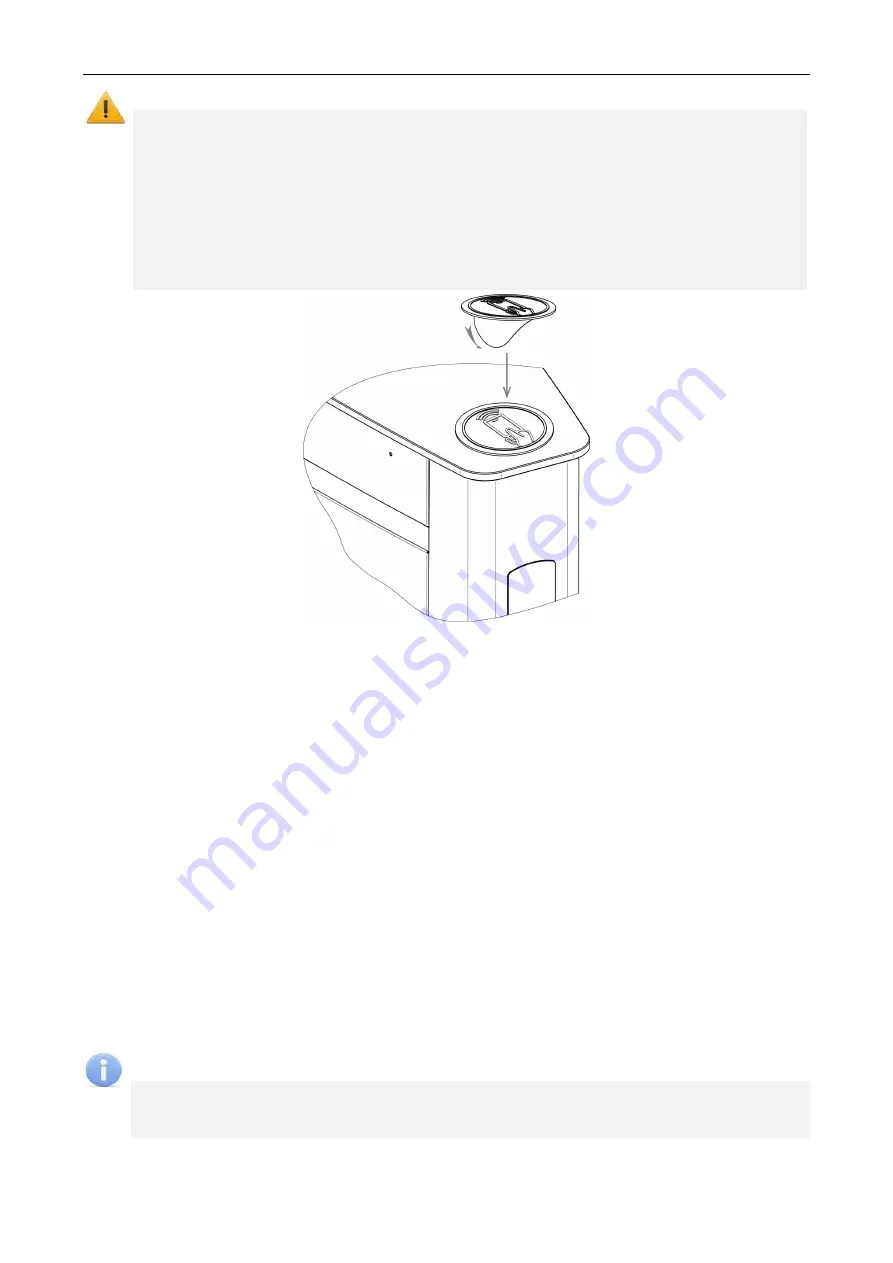

Attention!

During long-term and intensive operation of the turnstile with built-in readers, scratches and

scuff marks can appear on the glass surface either from access cards presentation (as well

as from wallets, bags, wristbands, watches, rings, etc.) or from cleaning substances with

abrasive inclusion.

Such damages are not a warranty case.

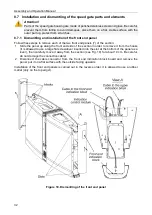

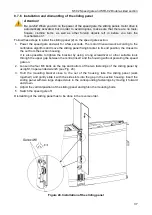

In order to prevent or remove such damages manufacturer has provided self-adhesive

rubber pads for card presentation areas (see Fig. 27). Moreover, consumer can use the

services of special companies providing professional glass polishing or purchase new

covers for replacement from PERCo.

Figure 27. Gluing rubber cover on glass top cover

8.7.9 The reduction of the passageway width of

STD-02.900

section

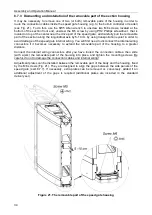

Design of the

STD-02.900

Double-sided section allows you to reduce the distance of departure of

the sliding panel from the housing to 280 mm in order to arrange the passageway with a width of

600 mm.

To do this, it is necessary to mount the sliding panel departure limiter:

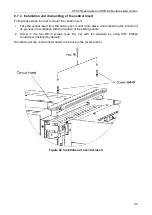

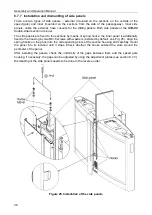

1. Remove the sliding panel from the required side of the section (see sect.8.7.6).

2. Stick the reflector supplied in the delivery set (see Fig. 28), so:

•

take a special template from the delivery set, install it in the sliding panel slot, as shown in

the figure;

•

remove the protective film from the adhesive surface of the reflector and stick it with a

strong push in accordance with the template, it is recommended to degrease and dry the

place of gluing;

•

remove the template, check the adhesion strength of the reflector.

•

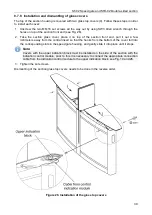

Install the sliding panel into its place (see sect. 8.7.6).

•

Turn off the power of the speed gate.

•

Install the two supplied special stops on the section housing and secure each with three

M4×8 screws (see Fig. 29):

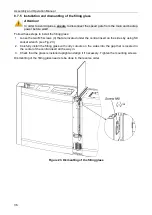

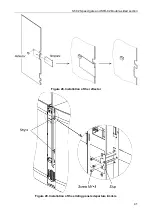

•

Install the jumper on the

XP3 "Mode"

connector of the motor drive board for this sliding

panel (see Fig. 30).

Note:

The sliding panel motor drive board is located under the glass top cover of the speed gate,

on the right side of the sliding panel and inside the gap of the section housing, see Fig. 6

(together with the control board from the

Master

section side).

•

Turn on and check the operation of the speed gate for each of the passageways

separately.