4.

In the

Offset from Reset Setpoint Selection

screen,

press

Up

or

Down

to select the Reset Setpoint Offset

value for the output. Select an OSET value to shift

the (floating) Reset Setpoint (RSP) that the output

references to a (floating) offset reset setpoint (RSP

+OSET).

- A positive offset value (OSET = +

n

) raises

the target reset setpoint referenced by the

output.

- A negative offset value (OSET = -

n

) lowers

the target reset setpoint referenced by the

output.

OSET is typically used to set up sequential off-

set reset setpoint values and stage multiple

Relay Outputs. For example, four boilers can

be staged with 0, 2, 4, and 6 (°F) OSET values

to stage the four boilers ON according to load

increases. (You can also enable bAL to load bal-

ance the boiler runtimes. See

the Load Balancing feature.) See Table 3 for the

range of usable OSET values for the outputs

with RSP in your control system.

Press

Next

to save your value and go to the

next screen.

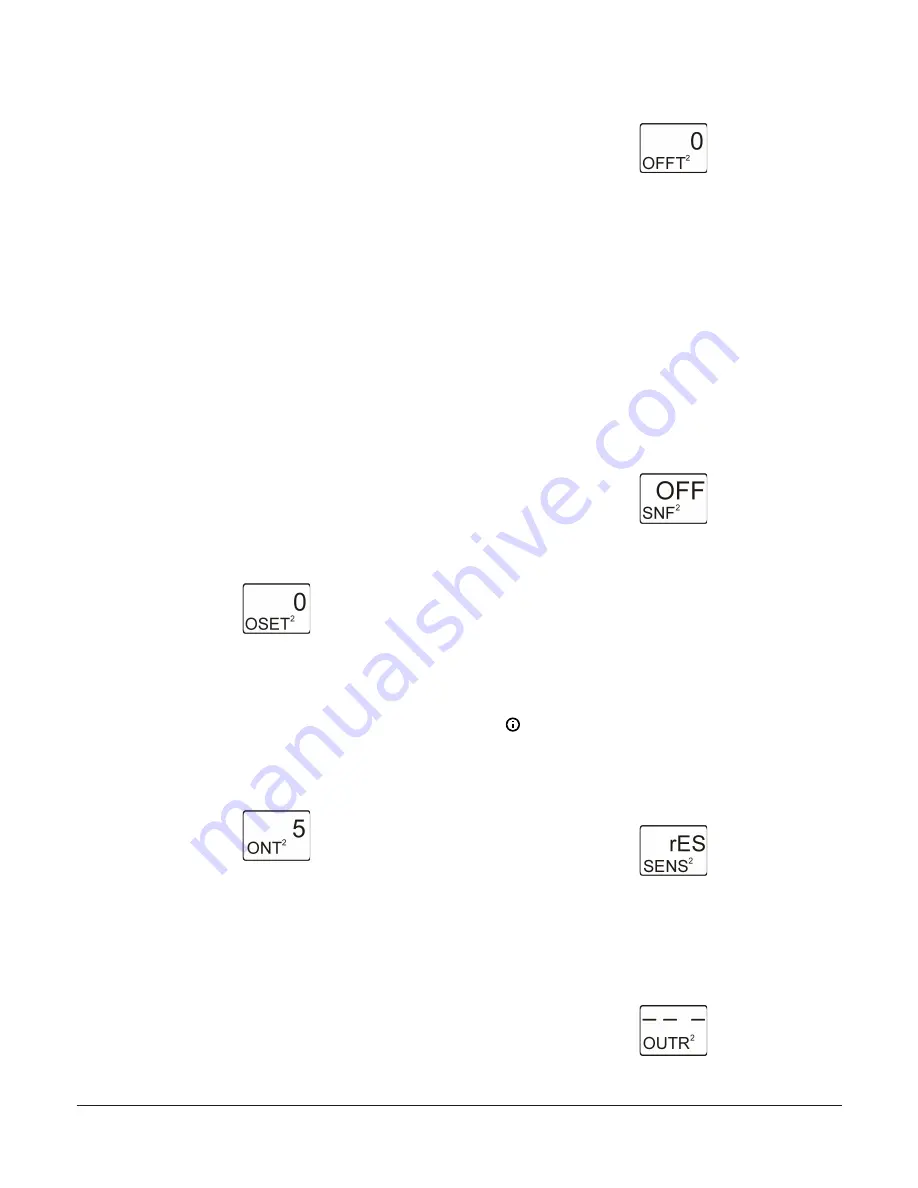

The following figure shows 0 (°F) offset selected

for Output 2.

Figure 38: Offset from Reset Setpoint Selection screen

5.

In the

Minimum Relay ON Time Selection

screen,

press

Up

or

Down

to select the minimum time that

the output relay remains On after reaching the

Relay ON value. Minimum ON Time range is 0 to 300

seconds. Press

Next

to save your selection and go to

the next screen.

The following figure shows 5 seconds selected

for the minimum ON-Time for Output 2.

Figure 39: Minimum Relay ON Time Selection screen

6.

In the

Minimum Relay OFF Time Selection

screen,

press

Up

or

Down

to select the minimum time that

the output relay remains Off after reaching the Relay

OFF value. Minimum OFF Time range is 0 to 300

seconds. Press

Next

to save your selection and go to

the next screen.

The following figure shows 0 seconds selected

for the minimum OFF-Time for Output 2.

Figure 40: Minimum Relay OFF Time Selection screen

7.

In the

Sensor Failure Mode Selection

screen, press

Up

or

Down

to select the output’s mode of operation

if the referenced sensor or sensor wiring fails. The

output operates in the selected mode until the

failure is remedied.Sensor Failure mode selections

for Relay Outputs include:

-

ON

—output relay remains On during sensor

failure.

-

OFF

—output relay remains Off during sensor

failure.

Press

Next

to save your selection and go to the

next screen.

The following figure shows OFF sensor failure

mode selected for Output 2.

Figure 41: Sensor Failure Mode Selection screen

8.

To change the output’s sensor, press

Up

or

Down

in

the

Edit Sensor

screen to select the sensor that the

output references. After you select a different sensor,

press

Next

to go to the required output selection

screen and repeat the output setup procedure for

the new Sensor Type values.

If you do not need to change the output’s sen-

sor, press

Next

in the

Edit Sensor

screen to

save the current sensor selection, complete the

output setup, and return to the Output Setup

Start screen.

Note:

If you change the sensor that an output

references, the default setup parameters and

values for the output change, and you must set

up the output again.

Figure 42: Edit Sensor screen

9.

The Relay Output with Reset Setpoint is now set up

in the UI. In the

Relay Output Setup Start

screen,

press

M

to scroll through the remaining Setup Start

screens and continue setting up your control system,

or press

Up

and

Down

simultaneously to return to

the System 450 Main screens.

Figure 43: Relay Output Setup Start screen

System 450 Series Reset Control Modules with Real-Time Clock and Relay Output Installation Guide

15