Figure 10: Sn-2 Sensor Type Selection screen

Note:

If your control system does not use

three sensors, simply press

Next

while the two

dashes are flashing in a Sensor Type Selection

screen to save no Sensor Type and go to the

next screen.

4.

In the

Sn-3 Sensor Type Selection

screen, press

Up

or

Down

to select the desired Sensor Type (°F, °C, rH,

or --). Press

Next

to save your selection and go to the

Temperature Offset Setup screen for Sn-1.

The following figure shows Sn-3 set to rH.

Figure 11: Sn-3 Sensor Type Selection screen

5.

Press

Up

or

Down

to select a temperature offset

value. Press

Next

and either:

- go to the next

Temperature Offset Selection

screen (if there are additional temperature

sensors in your control system) and repeat

this step for each temperature sensor.

- return to the

Sensor Setup Start

screen.

The following figure shows 0 as the selected

temperature display offset value for Sensor 2.

Figure 12: Temperature Display Offset Selection

screen

Select a temperature offset for each tempera-

ture (only) sensor in your control system. The

selected offset value is added to the sensed

temperature value to calculate the displayed

temperature value (sensed °F + OFFS = dis-

played °F). The Temperature Display Offset

value is typically 0 or a very low value.

Sensor Type

°F

enables an offset of +/- 5°F in 1

degree increments. Sensor Type

°C

enables an

offset of +/- 2.5°C in 0.5 degree increments.

6.

Press

M

to scroll through the remaining Setup Start

screens and continue setting up your control system,

or press

Up

and

Down

simultaneously to return to

the System 450 Main screens. The hardwire sensors

are setup in the UI.

Figure 13: Sensor Setup Start screen

Setting up the System 450 Reset

Setpoint

The System 450 Reset Control Modules feature

temperature and humidity setpoint reset capability based

on a Master temperature sensor (Sn-1) and a control loop

sensor (Sn-2).

You easily can set up a custom calculated (floating)

Reset Setpoint (RSP) that can be referenced by any of

the outputs in your control system. All control system

outputs that are set up to reference the Reset Setpoint

sensor (rES) use the same RSP setup parameters and RSP

to control output. During normal operation the current

RSP is displayed in one of the Main screens.

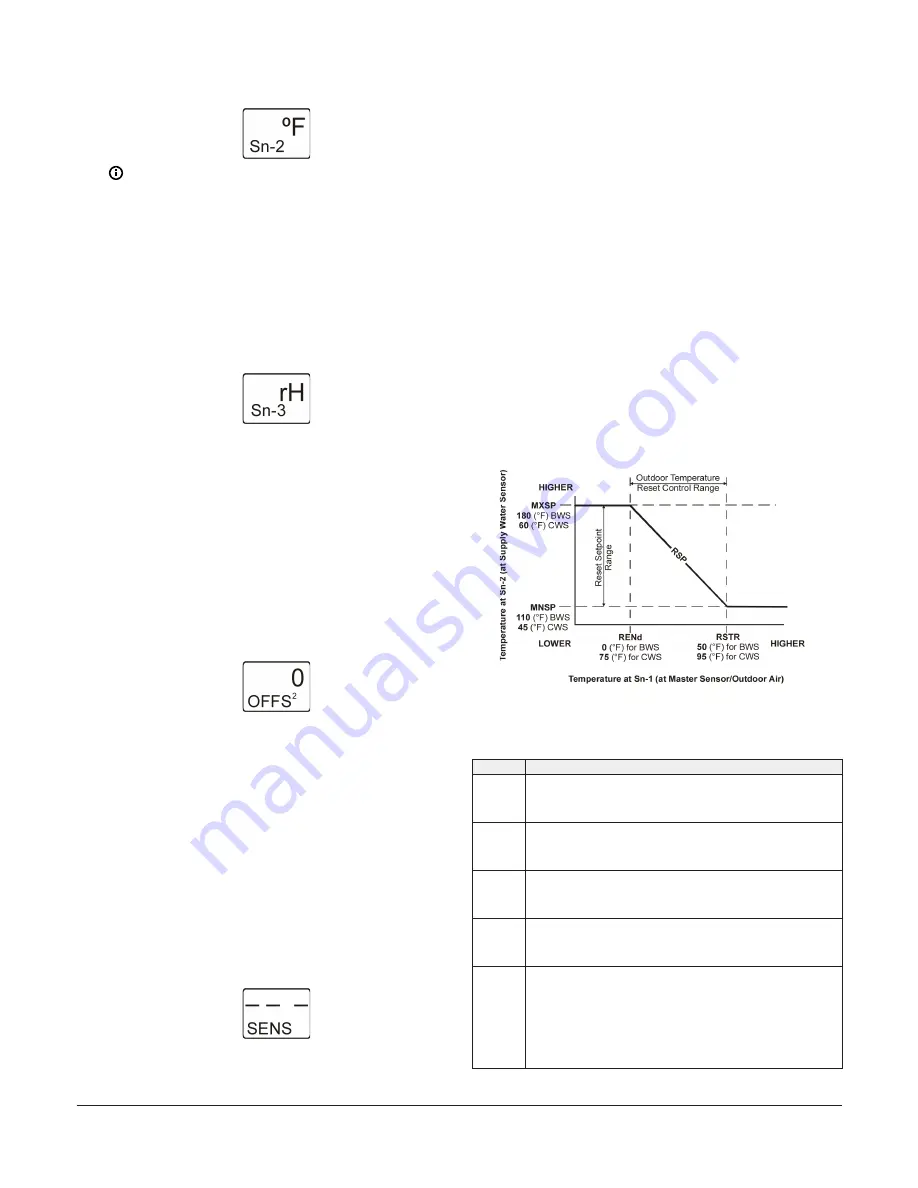

The following figure and table illustrate the relationships

between the setup parameters that define the calculated

RSP.

Figure 14: Example Reset Setpoint Applications for

Boiler Water Supply and Chiller Water Supply showing

the relationships between the Reset Setpoint Setup

parameters

Table 4: Example Reset Setpoint Applications for Boiler

Water Supply and Chiller Water Supply details

Item

Description

MNSP

Minimum Reset Setpoint

(110 [°F] BWS Temperature)

(45 [°F] CWS Temperature)

MXSP

Maximum Reset Setpoint

(180 [°F] BWS Temperature)

(60 [°F] CWS Temperature)

RSTR

Reset Range Start Temperature

(50 [°F] Outdoor Air for BWS)

(95 [°F] Outdoor Air for CWS)

RENd

Reset Range End Temperature

(0 [°F] Outdoor Air for BWS)

(75 [°F] Outdoor Air for CWS)

RSP

Calculated (Floating) Reset Setpoint

From 0 to 50°F outdoor air, the Boiler Water Supply (BWS) setpoint is reset

between 180 and 110°F. Above 50°F outdoor air, the BWS setpoint is 110°F.

Below 0°F outdoor air, the BWS is 180°F.

From 75 to 95°F outdoor air, the Chiller Water Supply (CWS) setpoint is

reset between 60 and 45°F. Above 95°F outdoor air, the CWS setpoint is

45°F. Below 75°F outdoor air, the CWS is 60°F.

System 450 Series Reset Control Modules with Real-Time Clock and Relay Output Installation Guide

9