Rim lock and pump tires:

Warning! Tyres can explode due to the following:

1. The rim and the tyre are not the same size.

2. The tyre or rim is defective.

3. The tyre pressure is above max. pressure

recommended by the manufacturer.

4. The operator fails to comply with the safety

regulations.

Pump the tire

Check that the tyre is in good condition and make

sure that there is no damage before you start

pumping. Keep your hands and body as far away

from the tyre as possible. Install the valve core if it

has been removed. To inflate the tire, connect the

air filler nozzle to the tyre valve stem. Make sure

that the air filler nozzle is completely depressed

over the threads of the valve stem. When the air

filler nozzle is in place, lock it to the valve stem by

releasing the locking device. As soon as the tyre

has reached the correct tyre pressure, loosen the

air filler nozzle from the valve stem and screw on

the valve cap. The tyre is inflated with short

inflations while checking the tyre pressure.

Note:

1. Failure to follow all warnings and instructions

could result in serious injury or death to the

operator or attendant. Never exceed 3.5 bar

(50 psi) when attaching clinch or inflatable

tires.

2. If higher tyre pressure is necessary, remove the

wheel from the tyre changer and continue the

inflation procedure with the wheel inside a

special protective cover. Never exceed the

maximum air pressure specified by the tyre

manufacturer.

3. Only specially trained persons may perform

these operations. Do not allow others to use or

be near the tyre changer.

Moving the machine

Use a forklift to move the machine. Disconnect the

tyre changer from the mains and the pneumatic air

supply, lift the base plate and insert the feet of the

forklift trucks. Then mount the tyre changer to a

new position and fix it properly.

Note! The location chosen for fixing the tyre

changer must comply with the safety regulations.

Maintenance

Warning: Only professionals

can perform maintenance. To

extend the life of the

machine, maintain the

machine carefully according

to the operating instructions.

Otherwise, it will affect the

reliability of the machine or

even damage the operator

and others nearby.

Warning: Before performing maintenance,

disconnect the tyre changer from the mains, power

supply and pneumatic air supply, and depress the

hooks so that they are open and close the

mounting table pedal. Depress 3 ~ 4 times to

evacuate all compressed air from the machine.

Damaged parts must be replaced by professionals

with spare parts provided by the manufacturer.

• Clean the machine once every day after the

operation. Clean the dirt on the mounting table

with diesel oil once a week and lubricate the

slides and clamps.

• Subsequent maintenance must be done at least

once a month: Check the oil level in the oil feed

machine, top up with SAE30 # oil if

necessary.

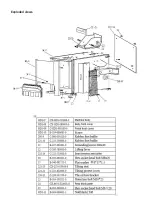

Unscrew with Allen

key (E). Based

on the

connection of

compressed

air, first push up

the hooks and step

on the pedal to the

assembly table 5-6

times, and check if oil

falls into the oil cup. For continuous operation,

press twice each time, drop an oil drop,

otherwise adjust the screw (D) that checks that

the oil enters (Fig. 19).

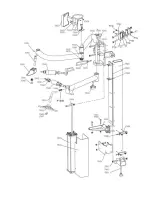

• As shown in Figure 19-1, when you find that

there is some water in the cup, push up the

drain valve to drain water with your fingers.

Release your finger after draining the water, the

drain valve closes automatically.

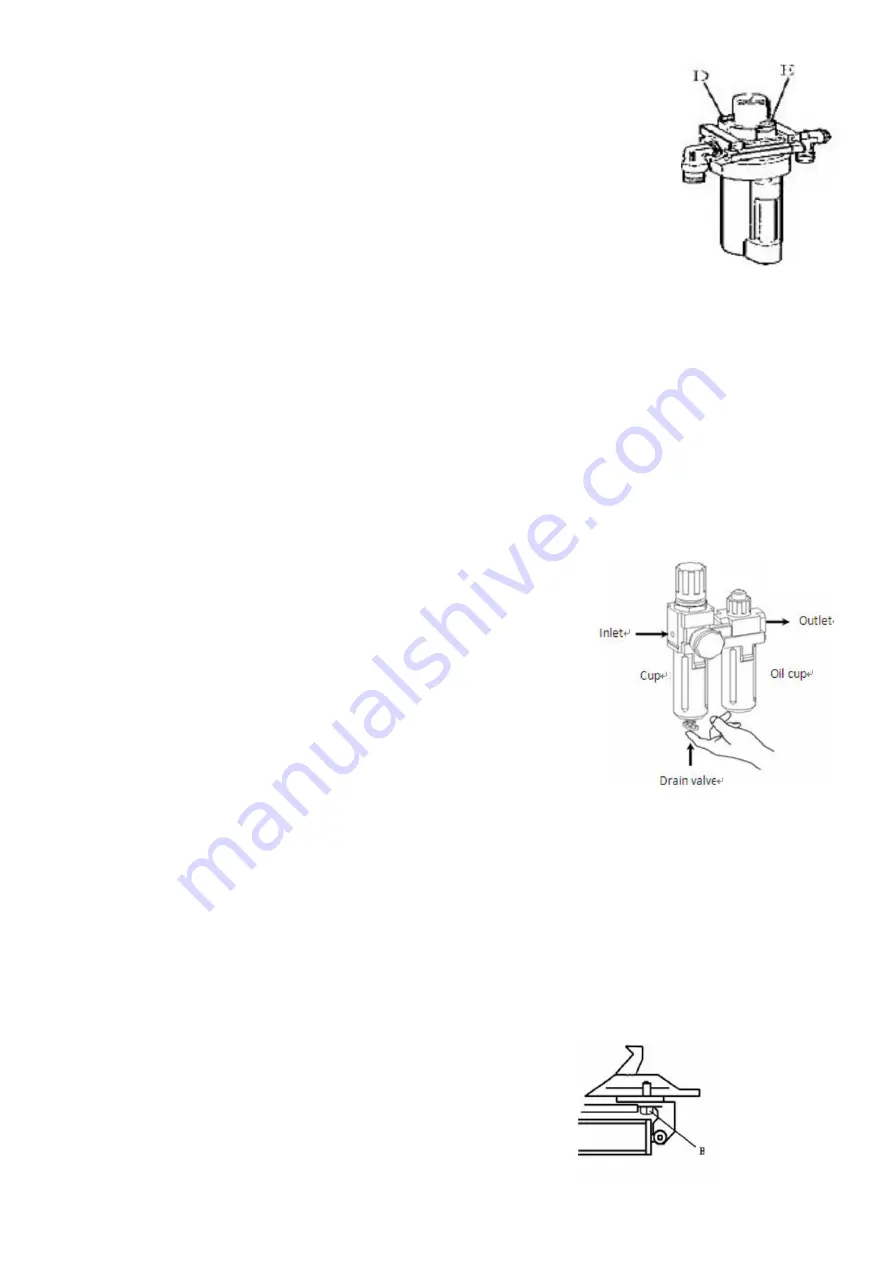

Note! After the first 20 days, tighten the hooks with

the tightening screws (B) on the mounting table

(Fig 20).

Fig 19

Fig 19.1

way down (Fig. 17,

position 2), a strong air blow should come from the

holes in the four hooks’ locking controls. (Fig. 18)

Summary of Contents for 507083

Page 1: ...Tyre changer U 6656AT Däckmaskin U 6656AT en hastighet Item No 507083 ...

Page 10: ......

Page 19: ...Exploded views ...

Page 20: ......

Page 21: ......

Page 22: ......

Page 23: ......

Page 24: ......

Page 25: ......

Page 26: ......

Page 27: ......

Page 28: ......

Page 29: ......

Page 30: ......

Page 31: ...Wiring diagram ...

Page 32: ......