28

condition. Repair or replace any missing or damaged

4. Perform lubrication.

3. Make sure all shields are in place and in good

5. Listen for abnormal sounds, which might indicate

loose parts, damaged bearings, or other damage.

Correct any deficiency before continuing operation.

shields.

6. With the engine off, engage the blower assembly.

cracks or tears.

7. Check for wear or deterioration of the upper or lower

Check the belt tension and inspect the pulley belt for

After Each Use:

1. Clean all debris from machine especially from the

decals. Replace any missing or illegible decals.

PECO parts.

been torn or worn through, replace with genuine

hoses. If there are any portions of the hose that have

container, underneath the belt shields, and safety

2. Inspect the unit for worn or damaged components.

Repair or replace before the next use. Any

replacement component installed during repair shall

include the component’s current safety decal specified

3. Check belt for proper tension.

by the manufacturers to be affixed to the component.

DOCUMENT THE FOLLOWING INFORMATION FOR FUTURE REFERENCE

Unit Model Number:_______________________________________________

Unit Serial Number:________________________________________________

Unit Engine Size:__________________________________________________

Date of purchase:________/________/_________

Address: _________________________________ State:_______ Zip:_______

Dealer/Distributor Name:__________________________________________

Phone Number: ____________________________________________________

100 AIRPORT ROAD

(800) 438-5823 OR (828) 684-1234 FAX: (828) 684-0858

EMAIL: [email protected]

ARDEN, NORTH CAROLINA 28704

WEBSITE: www.lawnvac.com

Lubrication

Gearbox:

1. Every 20 hours of use: Check oil levels in gearbox.

2. First 60 hours of use: Change oil.

3. Every 100 hours of use: Change oil.

NOTE:

Oil in gearbox should cover the gears. If not,

drain the gearbox and fill using an 80W-90 gear oil.

contain a greaseable zirc fitting. Newer models

recommend replacing with a measured 5.5 oz. to fill

NOTE:

Use only white lithium based grease for

SECTION V - PARTS & SERVICE

Collection system owners should record the name and

telephone number of their Service Center. Your Service

Center will be happy to supply replacement parts,

accessories, and do any service or repairs to your

collection system. If for any reason your Service Center

is unable to service your collection system or supply

replacement parts, contact Country Clipper and include

the following information on the chart below.

The gearbox ships with 6.0 oz. of oil, but we

NOTE:

The following is for older PTO models that

contain maintenance-free bearings and are without

.

a greasable fitting.

lubrication of the shaft on the blower assembly.

Parts And Service Information

Blower Assembly:

1. On initial use: Grease the fitting on the blower shaft.

the gearbox.

DO NOT OVERFILL!

2. Every 25 hours of use: Re-grease the grease fitting.

Summary of Contents for Pro 12 DFS 52621201

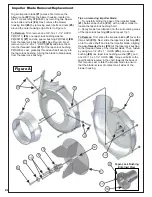

Page 16: ...16 ALUMINUM GRASS CONTAINER EXPLODED VIEW A0614 K1442 V1 131 6...

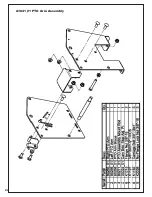

Page 22: ...22 A1841_01 PTO Arm Assembly...

Page 23: ...23 A1941_01 PTO Base Assembly Exploded Parts View...

Page 24: ...24 A1941_01 PTO Base Assembly Exploded Parts List...

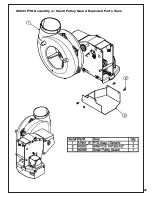

Page 25: ...25 A0623 PTO Assembly w Small Pulley Guard Exploded Parts View...

Page 26: ...26...

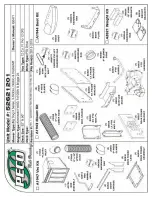

Page 30: ...30...

Page 31: ...31 NOTES...