12

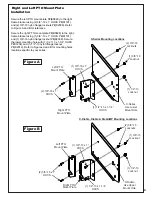

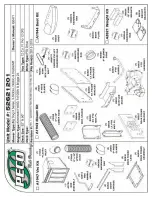

Thread (1) 5/16”-18 jam nut P#(K0120) onto each end of

(2) 5/16”-18 x 2-1/2” HHCS P#(K0125). Now partially

thread the bolts into each of the two tabs located on the

blower housing. Place blower cone P#(E6009) so the

two tabs line up with the bolts then tighten completely.

See Figure B.

Blower Cone Installation

Cam Assembly Adjustment

The cam assembly P#(A0422), which controls the

blower belt tension, comes from the factory pre-adjusted.

If the belt is too tight or becomes too loose, remove the

hair pin clip P#(K0099) from the belt tension rod

P#(K0326) and pull the “L” end of the rod out of it’s hole

in the cam assembly. The tension rod may then be

screwed out to tighten the belt or screwed in to loosen

the belt. Replace the “L” end into the top hole in the cam

and replace the hair pin clip. Adjust the cam stop bolt

P#(K1159) to allow the cam to rotate slightly over center

when the blower is disengaged (Figure A).

Cam Assembly

Tension Rod

Cam Stop

Blower

Cone Tabs

Blower

Cone

Hair Pin Clip

(2) 5/16”-18 x 2-1/2”

All Thread HHCS

(2) 5/16” Jam Nuts

Figure A

Figure B

Summary of Contents for Pro 12 DFS 52621201

Page 16: ...16 ALUMINUM GRASS CONTAINER EXPLODED VIEW A0614 K1442 V1 131 6...

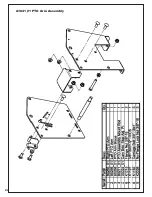

Page 22: ...22 A1841_01 PTO Arm Assembly...

Page 23: ...23 A1941_01 PTO Base Assembly Exploded Parts View...

Page 24: ...24 A1941_01 PTO Base Assembly Exploded Parts List...

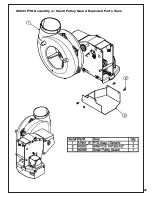

Page 25: ...25 A0623 PTO Assembly w Small Pulley Guard Exploded Parts View...

Page 26: ...26...

Page 30: ...30...

Page 31: ...31 NOTES...