5 Handling Precautions for Traverse Unit

The laser diode in the optical pickup unit may break down due to static electricity of clothes or human body. Special care must be

taken avoid caution to electrostatic breakdown when servicing and handling the laser diode.

5.1. Cautions to Be Taken in Handling the Optical Pickup Unit

The laser diode in the optical pickup unit may be damaged due to electrostatic discharge generating from clothes or human body.

Special care must be taken avoid caution to electrostatic discharge damage when servicing the laser diode.

1. Do not give a considerable shock to the optical pickup unit as it has an extremely high-precise structure.

2. To prevent the laser diode from the electrostatic discharge damage, the flexible cable of the optical pickup unit removed should

be short-circuited with a short pin or a clip.

3. The flexible cable may be cut off if an excessive force is applied to it. Use caution when handling the flexible cable.

4. The antistatic FPC is connected to the new optical pickup unit. After replacing the optical pickup unit and connecting the flexible

cable, cut off the antistatic FPC.

5.2. Grounding for electrostatic breakdown prevention

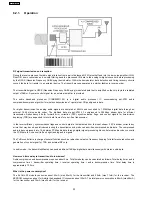

Some devices such as the DVD player use the optical pickup (laser diode) and the optical pickup will be damaged by static

electricity in the working environment. Proceed servicing works under the working environment where grounding works is

completed.

5.2.1. Worktable grounding

1. Put a conductive material (sheet) or iron sheet on the area where the optical pickup is placed, and ground the sheet.

5.2.2. Human body grounding

1. Use the anti-static wrist strap to discharge the static electricity form your body.

9

SA-HT640WPL

Summary of Contents for SA-HT640WPL

Page 4: ...23 2 Packaging 109 24 Replacement Parts List 110 24 1 Component Parts List 111 4 SA HT640WPL ...

Page 10: ...10 SA HT640WPL ...

Page 16: ...16 SA HT640WPL ...

Page 19: ...8 2 Detail Block Diagram Receiver module 19 SA HT640WPL ...

Page 31: ...31 SA HT640WPL ...

Page 37: ...10 1 Disassembly Flow Chart 37 SA HT640WPL ...

Page 38: ...10 2 Main Components and P C B Locations 38 SA HT640WPL ...

Page 46: ...Step 3 Push tray assembly to the direction of arrow shown 46 SA HT640WPL ...

Page 53: ...14 2 Main P C B 53 SA HT640WPL ...

Page 60: ...SA HT640WPL 60 ...

Page 68: ...SA HT640WPL 68 ...

Page 70: ...70 SA HT640WPL ...

Page 80: ...SA HT640WPL 80 ...

Page 86: ...SA HT640WPL 86 ...

Page 88: ...SA HT640WPL 88 ...

Page 97: ...97 SA HT640WPL ...

Page 104: ...21 3 4 2 Receiver Module P C B 104 SA HT640WPL ...

Page 106: ...23 Explode Views 23 1 Cabinet Parts Location 106 SA HT640WPL ...

Page 107: ...107 SA HT640WPL ...

Page 108: ...108 SA HT640WPL ...

Page 109: ...23 2 Packaging 109 SA HT640WPL ...