4

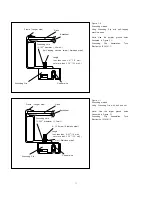

Install modules where they are not shaded

by obstacles like buildings and trees. Pay

special attention to avoid partially shading

the modules by objects during the daytime.

If needed, contact an Authorized

Representative with questions regarding

mounting profiles for Panasonic HIT

®

.

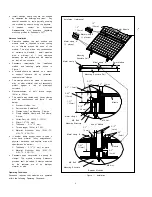

Notes on Installation

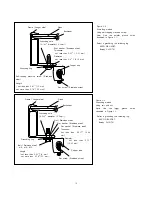

Clearance between the roof surface and

module frame is required to allow cooling

air to circulate around the back of the

module. This also allows any condensation

or moisture to dissipate. Install modules

with a minimum of 1 inch clearance

between the roof surface and the modules

so that air can circulate.

Panasonic recommends the installation

method and mounting profile shown in

Figure 1

A module should be attached on a mount

or support structure rail by corrosive-

resistant metal clamps.

The clamps should be made of aluminum

alloy or other material that will reasonably

protect against a risk of electrolytic

corrosion.

Recommendation of bolt torque range:

16N.m to 20N.m

The module was tested using Unirac clamps

with the specifications see figure 1 and

below;

Provider: UniRac, Inc.

Part number: SolarMount

®

Clamps type: Top Mounting Clamps

Clamp size:Mid clamp and End clamp,

C size,

Unirac Part No. 302003, 302101

Width: 1.5”(38 mm)

Thickness : 0.12”(3 mm)

Torque range: 16N.m to 20N.

Material: Aluminum Alloy (6005-T5,

6105-T5, 6061-T6)

If another clamp except Unirac is used it

must have material (alloy designations),

physical dimension and capture area with

specifications as bellow;

Thickness : 0.12”(3 mm) or more

Material: Aluminum Alloy (6005-T5,

6105-T5, 6061-T6)

Panasonic does not provide a warranty for

clamps. The module warranty Panasonic

provides shall be voided if clamps selected

by the customer are of an improper

material or size

Operating Conditions

Panasonic requires that modules are operated

within the following Operating Conditions:

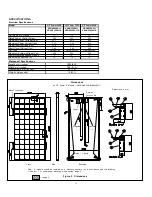

Installation (reference)

Solar Module

Metal clamp B

(2 places)

Metal clamp A

(2 places)

Mounting

Structure Rail

Metal clamp B

Solar Module

Metal clamp A

Mounting Structure Rail

Metal clamp B

Module

Mounting Structure

M8 Nut

Metal clamp A

M8 Bolt

M8 Bolt

M8 Nut

End of Module

Between Modules

Figure 1. Installation

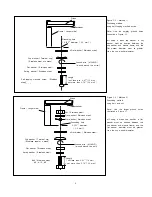

1.5”

(38mm)

0.12”

(3mm)

0.2” (5mm)

1.37”

(35mm)

0.18”

(4.6mm)

Mounting Structure

Module

0.62”

(16mm)

0.43”

(11mm)

0.2” (5mm)

0.12”

(3mm)

0.2”

(5mm)

0.2”

(5mm)

0.2”

(5mm)

1.5”

(38mm)