10 Copy mode

−

38

−

10 Copy mode

The

OPX-2A

has four data banks, and operation data and parameters can be saved in each of these data

banks. Since an EEPROM is used as the data memory element, stored data will be retained even after the

power is turned off.

In the copy mode, you can download data saved in the

OPX-2A

to the driver. You can also upload data

saved in the driver to the

OPX-2A

.

It is also possible to verify data in the

OPX-2A

against the corresponding data in the driver, or revert

driver data to their initial values.

10.1 What you can do in the copy mode

•

Download

Copy data saved in the

OPX-2A

to the driver.

•

Upload

Copy data saved in the driver to the

OPX-2A

.

•

Verification

Verify data in the

OPX-2A

against the corresponding data in the driver.

•

Initializing driver data

Revert data saved in the driver to their initial values.

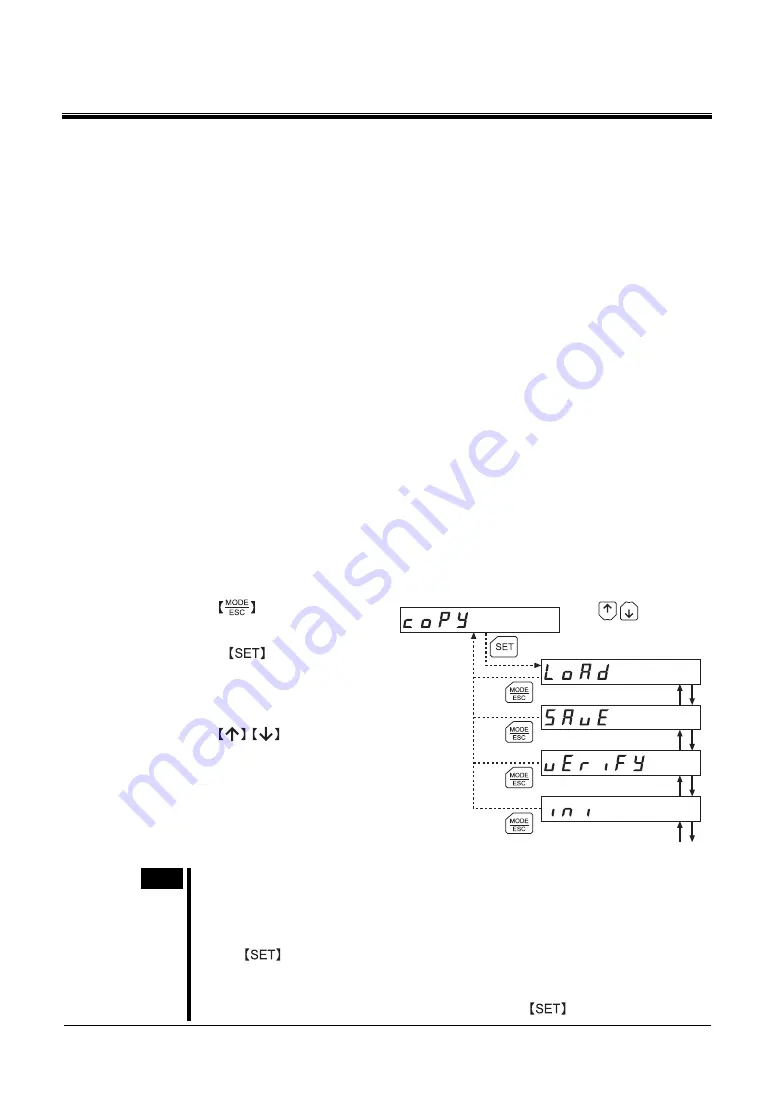

10.2 Operation in the copy mode

1.

Use the

key to select the

copy mode.

2.

Press the

key in the top

screen of the copy mode.

The display changes to the copy mode

item screen.

3.

Use the

keys to select

the item you want to perform.

Download

Top screen of the copy mode

Download

Upload

Verification

Initialization

Use

to navigate

through the items.

Note

•

Stop the motor operation before changing to the copy mode.

•

When you move from the top screen of the copy mode to a lower level, the START

input, FWD input, RVS input, HOME-P/PRESET input and M0 to M5 inputs will be

disabled.

•

If the

key on the

OPX-2A

is pressed while internal processing is being

performed via RS-485 communication, the top screen will not change to any of its

sub-screens and “mEm-bUSY” will be shown on the display. Be sure to wait until all

internal processing is completed, before pressing the

key.

Summary of Contents for OPX-2A

Page 43: ......