36

Adjust Exponential

Use the Coarse, Medium, and Fine scroll buttons to match the slope of the exponential red curve and the

associated data points at the smoothest range of surface values. Lasercheck measurements and actual

surface roughness eventually exhibit an exponential relationship as the surface values get very smooth (a

few microinches and below).

Step 5 Review

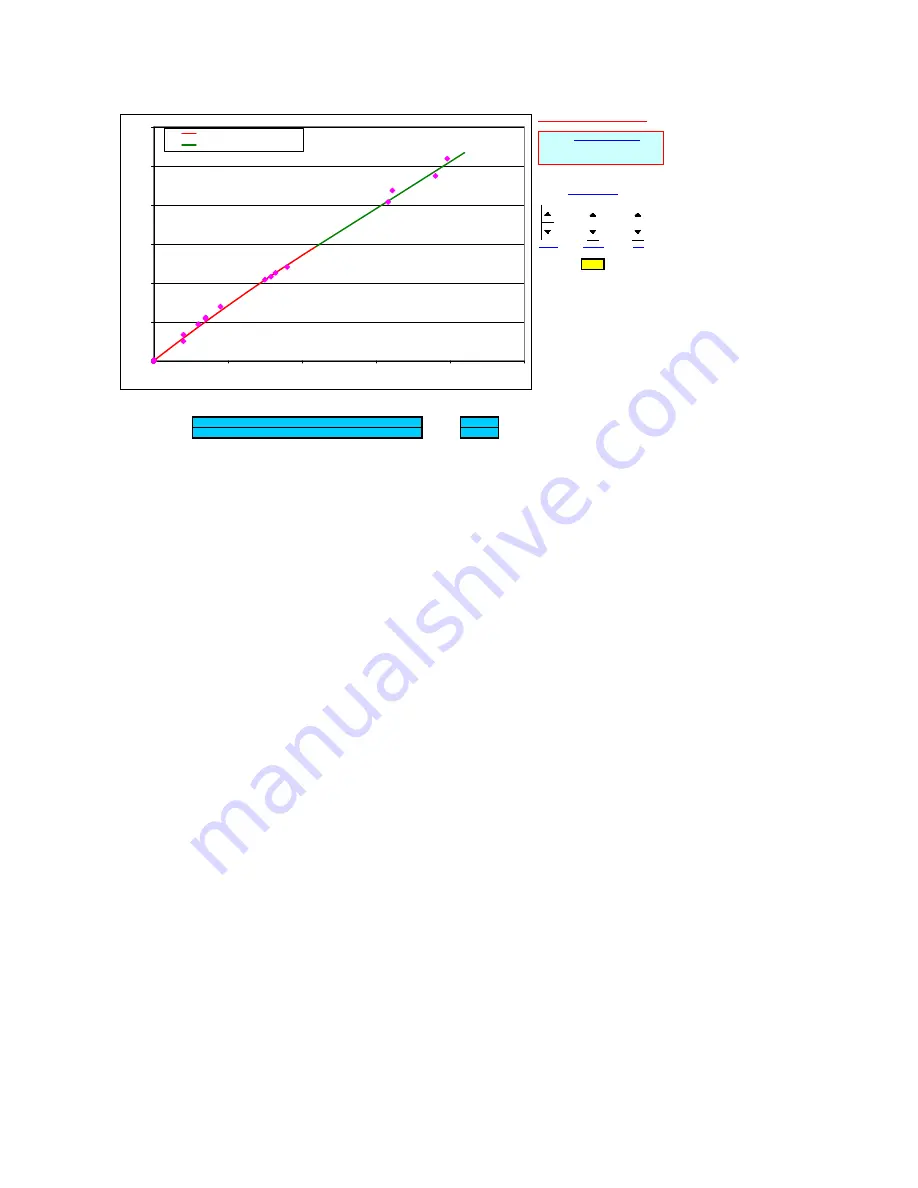

Below is an image of the Step 5 tab of the spreadsheet including instructions. This final graph allows you to

review the curve fitting of all regions of roughness that have been performed in Step 2 through Step 4. If

any regions of the best fit curves do not appear to “best-fit” the data, then go back to the relevant tabs and

step back through the process until “best possible fit” is obtained for all ranges of roughness.

INSTRUCTIONS FOR THIS PAGE

Adjust Exponential

Coarse

Medium

Fine

-0.50

1.10

Break Point

SMOOTH_CAL1

y =

-0.50

x^2 +

5.90

x +

0.00

1.10

SMOOTH_CAL2

y =

0.00

x^2 +

4.80

x +

0.60

5.10

Lasercheck Calibration Curve

0.0

2.0

4.0

6.0

8.0

10.0

12.0

0.0

0.5

1.0

1.5

2.0

2.5

Uncalibrated Lasercheck Measurements

A

ct

ua

l R

ou

gh

ne

ss

V

al

ue

s

y = -0.50 x^2 + 5.90 x + 0.00

y = 0.00 x^2 + 4.80 x + 0.60

1. Use the

Adjust Exponential

controls to best fit the

red

curve to the

smooth range of data points.