5699-E P-56

SECTION 4 INSPECTION, MAINTENANCE AND ADJUSTMENTS

3.

Adjusting Centralized Lubrication Unit

3-1.

Adjusting Pump Delivery

The delivery amount to each lubrication point is controlled by the metering type distribution valve,

and no further adjustment is necessary.

Metering type distribution valves are provided on the columns and saddle.

The delivery condition of lubricating oil can be checked visually. (Use sufficient care when checking

the delivery condition.)

3-2.

Maintenance and Countermeasure

When no lubricating oil is delivered:

•

Oil level is low.

Replenish the lubricating oil of the same brand.

•

The pump is at a rest: The pump operates intermittently.

The pump operation interval is set at about 10 minutes.

•

The filter at the oil filler port is clogged.

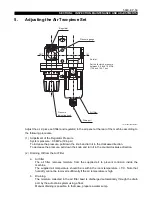

Clean the suction filter at least every six months. (See the figure below.)

•

The motor does not rotate. Check wiring.

3-3.

Other Remarks

•

The lubricating oil to be replenished must be clean and it must be of the same brand as cur-

rently used.

•

When cleaning the tank and the filter, NEVER USE THINNER OR TRICHLEN

(trichloroethylene) SHOWING HIGH VOLATILE CHARACTERISTICS.

•

Specified oil: G68 (ISO)

LE11214R0100600110001

The filter at the oil filler port