28

Alarms > Routing schedule

Routing schedule

S203 default alarm groups are:

• Group 1:

Urgent alarm that should always be immediately

routed.

• Group 2:

Malfunction alarms than can be frouted during busi-

ness hours.

• Group 3:

Service alarms or non-urgent alarms.

You can see where alarms are currently being routed from

the routing schedule menu. You can also set up a routing

schedule for each alarm group.

You can create a weekly schedule for each alarm group.

Weekly schedule have a general graphic view and an editing

view, where you can see to which alarm team each alarm is

sent at different times. In the graph, alarm teams are distin-

guished from each other by the bars with different thickness.

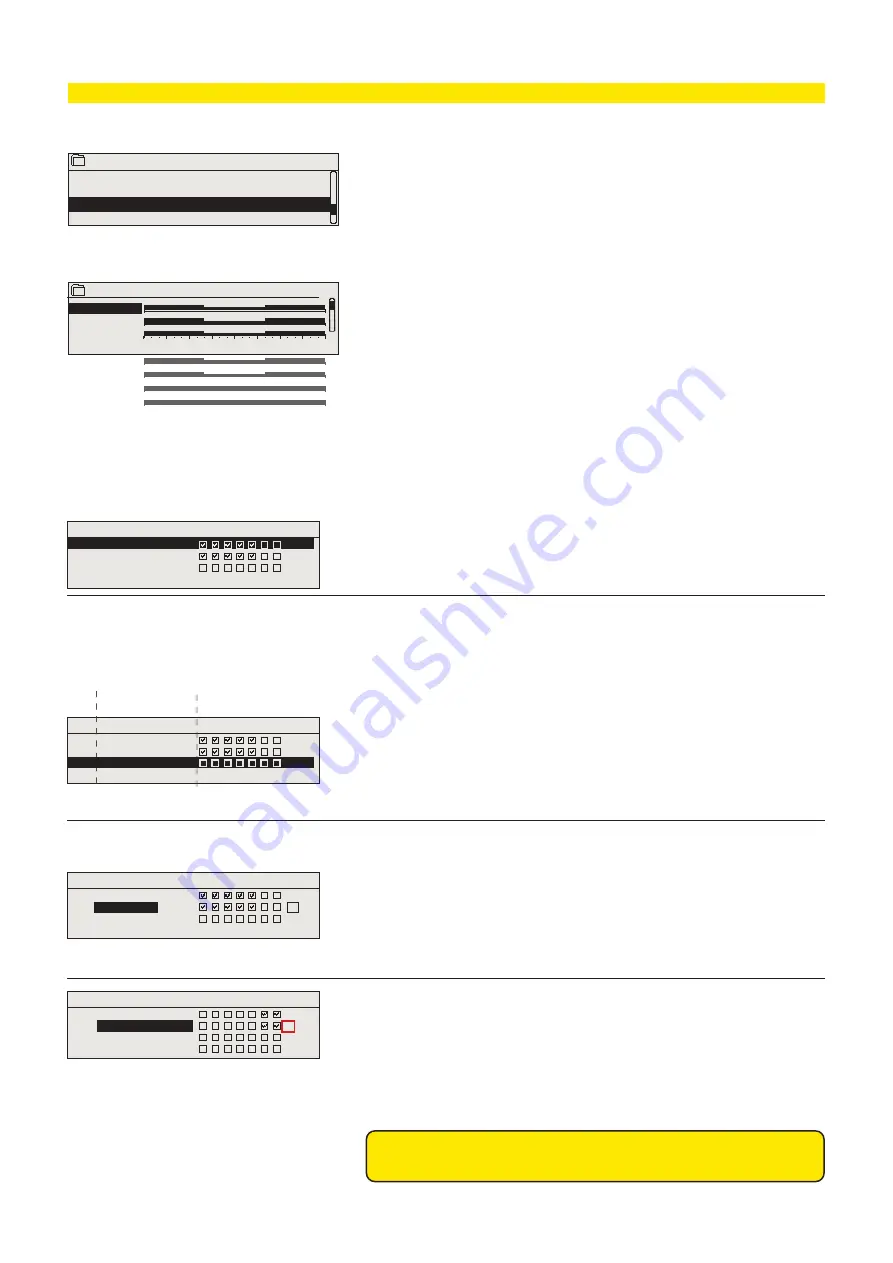

Editing view

Time Mode

Time Mode

Time Mode

M T W T F S S

M T W T F S S

M T W T F S S

OK

Deleting a switch time:

1. Turn the control knob to navigate to the switch time you wish to

delete and press OK.

2. Press OK at the alarm team and select ”Delete switch time”

3. Press OK at the end of the row.

4. To exit edit mode, press ESC.

1. Set switch time

2. Set alarm team

3.Select day(s)

Time Mode

08:00 Team 1

21:00

Delete switch time

00:00 Add new

M T W T F S S

OK

Browsing a weekly schedule:

An editing view opens, and it shows all the switch times and also to

which alarm teams alarms are routed at these times on the chosen

days.

Turn the control knob to browse a weekly schedule. If you wish to

see the exact switch times and names of alarm teams, or if you

wish to edit, remove or add switch times, press OK at any weekday.

Adding a new switch time:

1. Press OK at the “Add new” row.

2. Press OK. Set the switch time for alarm routing (set hours and

minutes separately) and press OK.

3. Press OK and then turn the control knob to set the alarm team or

the ”No routing” option. (No routing option means that alarms will

not be sent.) Accept by pressing OK.

4. Press OK at desired weekdays you wish to choose.

5. Press OK at the end of the row to accept the created schedule.

6. Press Esc to exit.

Editing a weekly schedule:

1. Turn the control knob to navigate to the value you wish to change

and press OK.

2. Turn the control knob to make the time and alarm team changes.

Press OK to accept.

3. Press the OK button to change the day of the week.

4. Press Esc to exit.

Graph

This example shows that group 1 alarms are

always forwarded. During business hours

(Monday - Friday 8:00 a.m. - 4:00 p.m.) alarms

are forwarded to different teams than during

evenings and weekends. More detailed

information is shown in the ”Editing view”.

Monday >

Tuesday >

Wednesda >

Thursday >

Friday >

Saturday >

Sunday >

0

3

6

9

12

15

18

21

24

Group 1 Weekly schedule

08:00 Team 1

16:00 Team 2

00:00 Add new

08:00 Team 1

16:00 Team 2

00:00 Add new

08:00 Team 1

16:00

No routing

00:00 Add new

Routing schedule

Group 1 Weekly schedule

Group 1 Alarm routing now Team 1

Group 2 Weekly schedule

Group 2 Alarm routing now Team 1

>

>

>

>

Alarms are routed according to the routing schedule. You can ac-

knowledge an alarm by forwarding the same message to the S203.