-

11

-

5- 4.

Checking and adjusting the rail vibration

The amplitude and frequency of the rail vibration can be adjusted.

The vibration has been adjusted at the factory for screws that correspond with

the rail.

Put some screws into the rail and turn the power on. If they are delivered

smoothly, there is no need for adjustment.

The screw transport feed differs depending on screw type.

For screws with a low transport speed, or screws that easily jump, perform the

adjustment according to the following procedure.

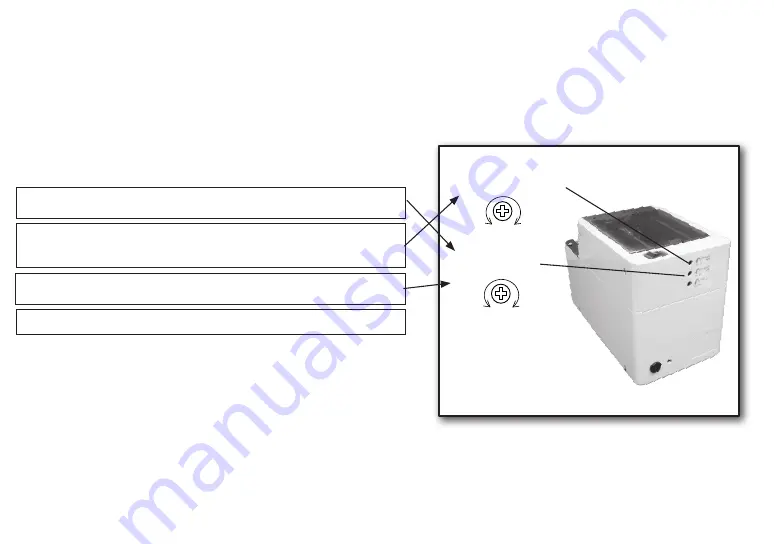

Frequency adjusting knob

Low

High

Amplitude adjusting

knob

Small

Large

Step1: Amplitude VOL Maximum

Step2: Frequency VOL Adjust where screew flows fastest.

(Around the middle)

Step3: If the vibration is too strong, decrease the amplitude.

Use the supplied resin driver. VOL may be damaged.

・

If the vibration is adjusted to a too large a value to increase the transport

speed, screws may jump from the rail and fall into the machine from the

clearance, failing to unload screws normally.

Adjust the vibration to a proper value that matches the loaded screws.

・

With the accompanying screwdriver, turn the knob without using excessive

force.

・

When no screws are scooped onto the rail for a certain period of time, the rail

vibration increases. If, still, no screws are scooped on to the rail, the machine

stops operating.