Illustration

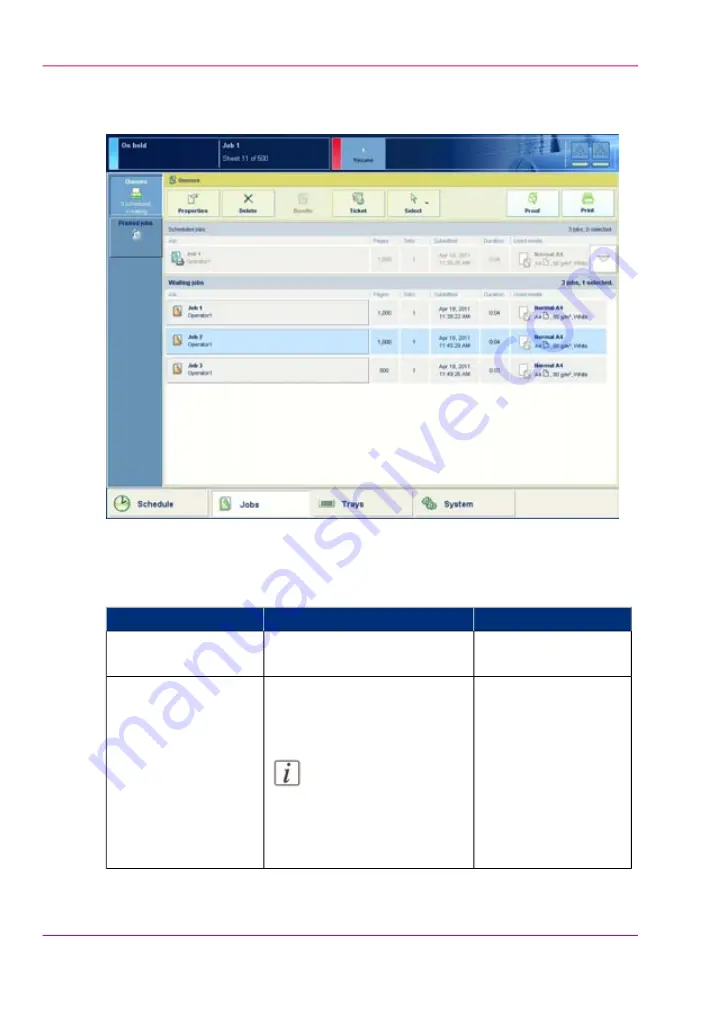

[27] The 'Waiting jobs' view

The items of the 'Waiting jobs' view of the 'Jobs' view

Description of the 'Waiting jobs' view

#

More information

Function

Item

Display the jobs that are not yet

scheduled for printing.

'Waiting jobs'

Check or change the properties

of a job. The button is only en-

abled when you select 1 job.

Note:

You can also press a job

2 times to check or

change the properties of

that job.

'Properties' button

Chapter 5 - Working with the operator panel

58

Introduction to the 'Jobs' view

Summary of Contents for VarioPrint 6000 MICR series

Page 1: ...o Oc VarioPrint 6000 Ultra Line Experience ultra speed User manual Operating information...

Page 7: ...Chapter 1 Preface...

Page 14: ...Chapter 1 Preface 14 Online support for your product...

Page 15: ...Chapter 2 Introduction...

Page 18: ...Chapter 2 Introduction 18 Available documentation...

Page 19: ...Chapter 3 Power information...

Page 25: ...Chapter 4 Overview of the system components...

Page 38: ...Chapter 4 Overview of the system components 38 The paper modules...

Page 39: ...Chapter 5 Working with the operator panel...

Page 178: ...Chapter 5 Working with the operator panel 178 Create a transaction setup...

Page 179: ...Chapter 6 Optional finishers and other devices...

Page 237: ...Chapter 7 Keeping the printer run ning...

Page 251: ...Appendix A Miscellaneous...