16

– ENGLISH

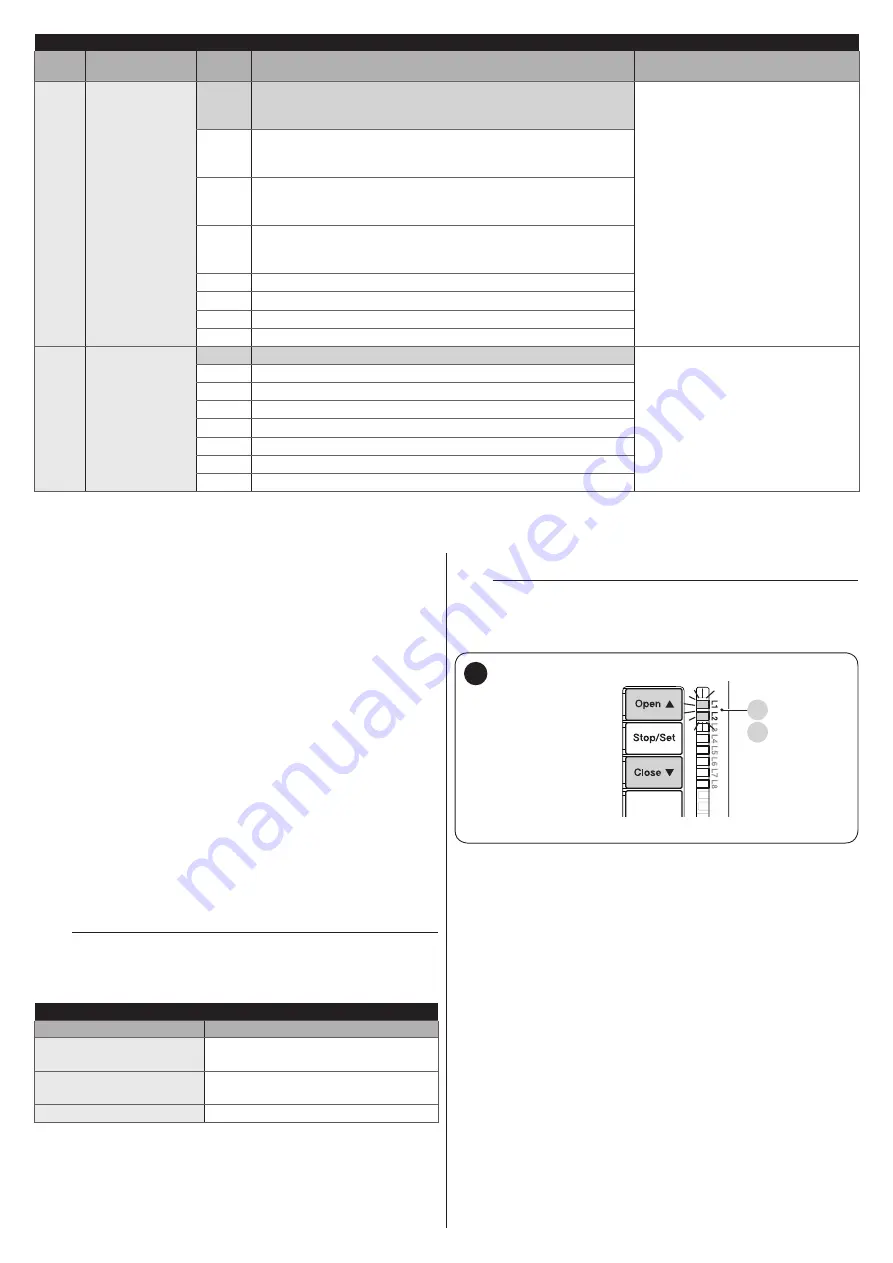

LEVEL 2 FUNCTIONS (ADJUSTABLE PARAMETERS)

Entry

LED

Parameter

LED

(level)

Set value

Description

L7

Programmable

input

configuration

L1

SbS input: step-by-step command

Open input: open command

Close input: close command

“PHOTO” operates only in the

closing manoeuvre.

L2

SbS input:

PHOTO

Open input:

open command

Close input:

close command

L3

SbS input:

step-by-step command

Open input:

PHOTO

Close input:

close command

L4

SbS input:

step-by-step command

Open input:

open command

Close input:

PHOTO

L5

Not used

L6

Not used

L7

Not used

L8

Not used

L8

List of

malfunctions

L1

Result of 1

st

manoeuvre (most recent)

Allows for verifying the type of

anomaly that occurred in the last 8

manoeuvres (see “

”

paragraph).

L2

Result of 2

nd

manoeuvre

L3

Result of 3

rd

manoeuvre

L4

Result of 4

th

manoeuvre

L5

Result of 5

th

manoeuvre

L6

Result of 6

th

manoeuvre

L7

Result of 7

th

manoeuvre

L8

Result of 8

th

manoeuvre

6.4 SPECIAL FUNCTIONS

6.4.1 “Move anyway” function

This function can be used to operate the automation even one

or more some safety devices fail to work properly or are out of

order. The automation can be controlled in “

hold-to-run

” mode by

proceeding as follows:

1.

send a command to operate the gate, using a transmitter or

key selector, etc. If everything functions properly, the gate

will move normally, otherwise proceed with point 2

2.

within 3 seconds, press the control again and hold it down

3.

after roughly 2 seconds, the gate will complete the requested

manoeuvre in “

hold-to-run

” mode, in other words, it will

continue to move so long as the control is held down.

6.4.2 “Maintenance notice” function

This function allows for signalling to the user when the automation

needs maintenance. The maintenance signal is given through a

lamp connected to the “

OGI

” output, if this output is configured as

a “

Maintenance indicator

”.

The configuration is only possible through the “Oview” programmer

Connecting the IBT4N interface

l

The various indicator lamp signals are shown in “

”.

Table 8

“MAINTENANCE INDICATOR” SIGNAL

Number of manoeuvres

Signal

Below 80% of the limit

Lamp stays lit for 2 seconds at the

start of the opening manoeuvre.

Between 81% and 100%

of the limit

Lamp flashes for the entire duration of

the manoeuvre.

Over 100% of the limit

Lamp flashes continuously.

6.5 MEMORY DELETION

m

The procedure described below restores the control

unit’s default settings. All the custom settings will

be lost.

L1

L2

20

To delete the control unit’s memory and restore all the default

settings, proceed as described below:

1.

press and hold the

f

and

h

buttons until

LEDs “

L1

” and “

L2

” start flashing

2.

release the buttons.

Summary of Contents for MC824HHS

Page 1: ...Nice MC824HHS Control unit EN Instructions and warnings for installation and use...

Page 24: ...24 ENGLISH NOTES...

Page 26: ...26 ENGLISH NOTES...

Page 27: ...ENGLISH 27 NOTES...