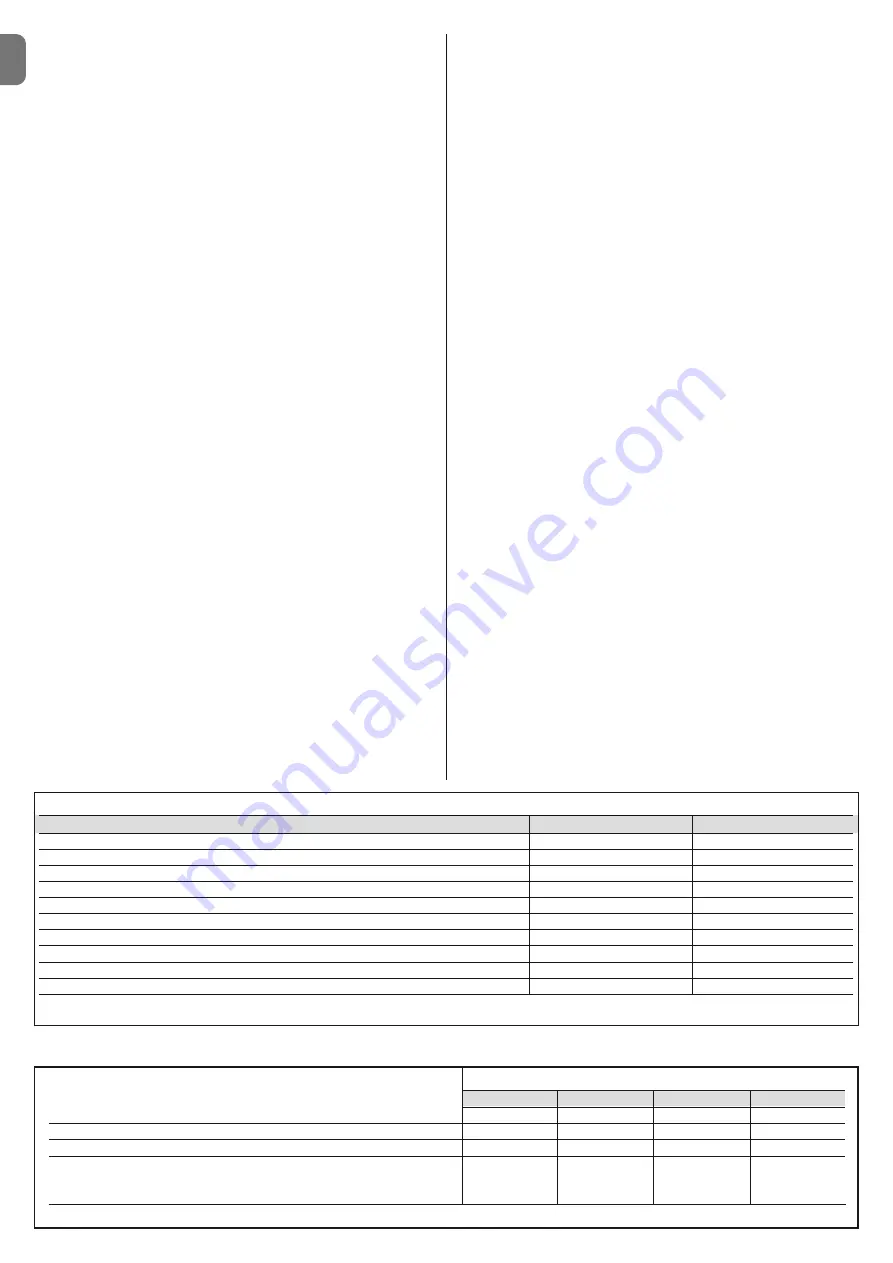

TABLE 1 - Essential requirements for CE marking (according to prospect ZA.1 of standard EN 13241-1)

Essential requirements

Point of standard

Result

Resistance to water

4.4.2

NPD

*

Release of hazardous substances

4.2.9

Compliant

Resistance to wind load

4.4.3

Compliant

Heat resistance

4.4.5

NPD

*

Permeability to air

4.4.6

NPD

*

Safe opening for vertically moving doors

4.2.8

Compliant

Definition of the geometry of glass components

4.2.5

NPD

*

Mechanical strength and stability

4.2.3

Compliant

Manoeuvring forces for power-operated doors/gates

4.3.3

Compliant

Durability of resistance to water, heat resistance and permeability to air

4.4.7

NPD

*

*

NPD = No Performance declared, when the product does not offer this performance, for example “Permeability to air”, or when the requirement is not applicable, such as “Definition

of the geometry of glass components”.

2

– English

EN

rier may not meet all the essential requirements.

The use of the product is

prohibited in these situations until the correspondence to the require-

ments of the directive has been verified by those performing the

installation

; in this case the “EC declaration of Conformity: appendix I” may

not be used. As a consequence, the installer in turn becomes the manufac-

turer of the “automatic barrier”, and must therefore observe all requirements

of the Machinery Directive 2006/42/EC. The manufacturer must complete a

risk assessment, which also includes the list of essential safety requirements

as stated in “appendix I of the Machinery Directive”, specifying the relative

solutions adopted. Note that the risk assessment is one of the documents

that constitutes the automation “technical documentation”. This must be

compiled by a professional installer with the possibility of using the “Declara-

tion of Conformity” in appendix II to be compiled by the installer of the road

barrier.

Special warnings regarding suitability of this product in relation to the

“Machinery” Directive 2006/42/CE; to be taken into consideration when

the installer becomes the manufacturer of the product

.

The road barrier is issued onto the market as a “quasi machine” and therefore

constructed for incorporation in a machine or to be assembled with other

machinery to produce a single “machine” in accordance with the Directive

2006/42/EC only in conjunction with the other components and in the ways as

described in this instruction manual. As established in directive 2006/42/EC,

this product may not be started up until the manufacturer of the machine, in

which this product is incorporated, has not identified and declared as compli-

ant with the directive 2006/42/EC.

• “Low Voltage” Directive:

Particular warnings concerning the suitable use of this product in relation to

the 2006/95/EEC “Low Voltage” Directive:

This product meets the requirements of the “Low Voltage” Directive if used as

specified in the configurations as envisaged in this instruction manual and in

combination with the articles listed in the product catalogue of Nice S.p.a.

These requirements may not be guaranteed if the product is used in configu-

rations or with other products that have not been foreseen; the use of the

product is prohibited in these situations until the correspondence to the

requirements foreseen by the directive have been verified by those perform-

ing the installation.

• “Electromagnetic compatibility” Directive:

Particular warnings concerning the suitable use of this product in relation to

the 2004/108/EEC “Electromagnetic Compatibility” 2004/10/EEC:

This product has been subjected to tests regarding the electromagnetic

compatibility in the most critical of use conditions, in the configurations fore-

seen in this instructions manual and in combination with articles present in

the Nice S.p.a. product catalogue..

The electromagnetic compatibility may not be guaranteed if the product is

used in configurations or with other products that have not been foreseen;

the use of the product is prohibited in these situations until the correspon-

dence to the requirements foreseen by the directive have been verified by

those performing the installation.

1.3.1 - Installation criteria and special warnings related to essential

requirements

This product, if correctly installed, complies with the essential requirements as

envisaged by the European Directive on “Construction Products” 89/106/EEC

according to the provisions of harmonised standard EN 13241-1, as specified

in

Table 1

; and by the European Directive on “Machinery” 2006/42/EC.

Important!

– If the road barrier is intended exclusively for vehicle transit, it

would be excluded from the field of application of EN 13241-1; in this case,

compliance with some of the requirements stated in Table 1 may not be com-

pulsory. Transit may be considered “exclusively vehicle” when there is an

express prohibition for other types (for example pedestrians), such as by using

adequate signs and, if other types are required, there is adequate space in the

immediate vicinity.

• Release of hazardous substances:

The product does not contain and/or release hazardous substances in con-

formity with the provisions of the standard EN 13241-1, point 4.2.9 and ac -

cording to the list of substances stated in the web site of the European Com-

munity *: http:// europa.eu.int/comm/enterprise/construction/internal/dangsub/

dangmain_en.htm

(

*

) Last update: 17/03/2003

Special warning to guarantee compliance with the requirement

– It is

essential that also all other materials used in installation, such as electric

cables, comply with this requirement

• Resistance to wind load:

Table 1a

specifies resistance of the pole supplied to the differential pressure of

the wind. The tests were performed with the pole fitted with the impact protec-

tion profile; other accessories may increase the exposed surface and thus

reduce the resistance to wind load.

• Safe opening for vertically moving doors:

The product does not cause uncontrolled movements or dropping of the pole

in the event of a fault on a single component of the suspension or balancing

(spring) system.

Special warnings to guarantee compliance with the requirements:

- Perform installation in strict observance of all instructions in chapters “

3 -

Installation

“ and “

5 - Testing and Commissioning

”.

- Ensure that a maintenance schedule is drawn up (for example, by using a

“Maintenance indicator” connected to the FLASH output associated with the

relative function - see Table 10); in which, all instructions in the chapter “Main-

tenance Schedule” must be strictly followed.

• Mechanical strength and stability of the product:

The product is designed and constructed to ensure that, during normal use, all

forces applied, impact and normal wear will not damage or impair mechanical

performance.

Caution:

See specifications for the requirement “Safe opening for vertically

moving doors”.

• Manoeuvring forces for power-operated doors/gates:

The operating forces applied by the pole in relation to the risks of crushing and

impact are protected by means of one of the three following methods:

1 For operation with “hold-to-run” controls:

as specified in EN 12453:

2000, point 5.1.1.4. In this case the control button must be located in sight of

the automation, and if accessible by the public, the control must not be avail-

able to the latter, for example protected by means of a key-operated selector

switch.

2 For “semi-automatic” operating mode:

by force limitation as specified in

EN 12453:2000, points 5.1.1.5 and 5.1.3.3.

TABLE 1a

Barrier

M3BAR

M5BAR

M7BAR

LBAR

Class

4

4

2

2*

Wind load [Pa]

≤ 1000

≤ 1000

≤ 450

≤ 450

Maximum wind speed [Km/h]

155

155

104

104

Descriptive term

Hurricane

Hurricane

Violent storm

Violent storm

Squall

Squall

*

Class 2 is achieved using accessory model WA11

Summary of Contents for M3BAR

Page 2: ......

Page 26: ......

Page 30: ...II 4 3 b a c d g h f e c a b...

Page 31: ...III 5 6 MBAR a c d b...

Page 32: ...IV 90 8 9 MBAR a b c a b 7 a b...

Page 33: ...V 180 10 11 LBAR c a a b...

Page 34: ...VI 13 14 12 LBAR c a b...

Page 35: ...VII 15 16 18 17...

Page 36: ...VIII 19 20 21 23 22...

Page 37: ...IX 24 26 25 28 1 cm 27 29...

Page 38: ...X 33 34 30 31 32 c a b c a b...

Page 39: ...XI 35 36 37 45 38 a b a b c...

Page 41: ...XIII 42 43 44 STOP 45 46 LIGHT 47...

Page 42: ...XIV 48 49 50 a b c...

Page 43: ...XV 51 52 a b...

Page 44: ...XVI 53 a b c d e f g...

Page 46: ...XVIII F1 F1 F2 F2 55...

Page 47: ......

Page 48: ...ISTML BARR01 4865_07 10 2011 www niceforyou com Nice SpA Oderzo TV Italia info niceforyou com...