EN

16

– English

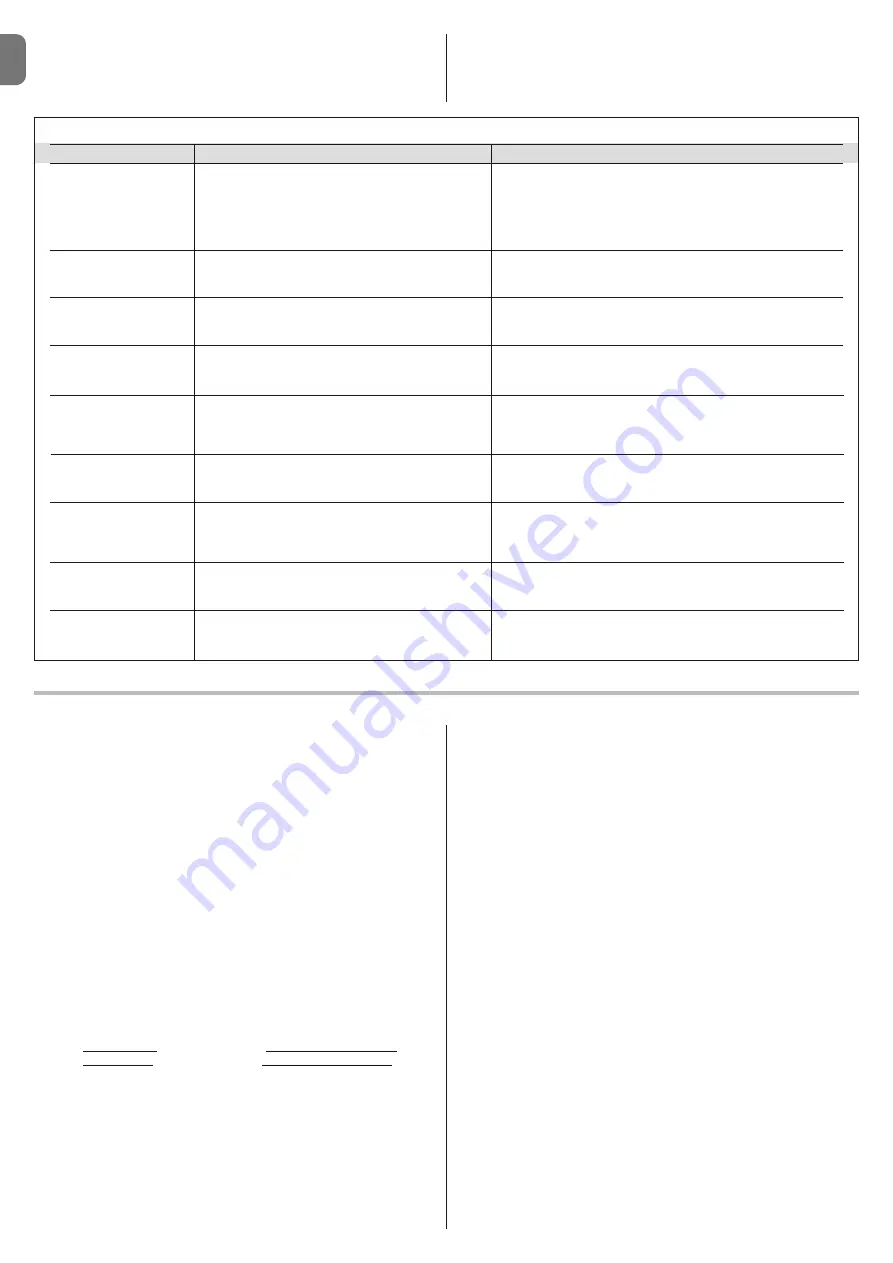

7.4.2 - Flashing light signals

If a flashing light is connected to the FLASH output on the control unit (or the

LED flashing light is used, optional accessory), during the performance of a

manoeuvre this emits a flash each second. If faults occur, the flashing light will

emit shorter flashes; these are repeated twice, separated by a 1 second pause.

The same signals are also emitted by the LED flashing light (optional accesso-

ry) and the “Bluebus” LED. Table

14

shows the cause and solution for each

type of signal.

7.5 - Loop Detector

The control unit has two circuits used to detect metal masses (motorcycles,

cars, trucks, etc…); each circuit may be completed with the use of a inductive

loop, consisting of 1 unipolar cable, to be positioned below the ground at a

depth of a few centimeters.

7.5.1 - Operation

When the control unit detects a variation in frequency with the passage of a

metal mass above the loop, it activates a manoeuvre or an output (output 1, 2,

3) to activate the flashing light, the open barrier indicator or the lights for the

pole. The factory setting controls an opening manoeuvre of the pole; until the

loop is operating, it is not possible to control the closing manoeuvre.

When the control unit is powered, it carries out a calibration, i.e. a measure-

ment of the operating frequency of each loop; if no loop is connected to the

control unit, the circuit automatically turns off after 30 seconds.

There are 8 levels of “metal mass detection sensitivity” (see Table 7 chapter 6).

The factory setting is 90%.

By using the Oview programmer, it is possible to modify the other parameters

and operating modes associated to the Loop Detector.

The following programs are possible, also see

Table 15

for the values:

• Loop sensitivity:

set the minimum frequency variation of the metal mass,

required to activate the manoeuvre. Reference parameters:

- set a “high sensitivity” for the detection of small sized metal masses

- set a “low sensitivity” for the detection of large sized metal masses.

• Loop power supply:

activates or deactivates the circuits of the loop detec-

tor.

• Activate loop 1, 2:

the activation of the loop makes the movement of the

barrier activate according to the set operating mode. If the function is DEAC-

TIVATED, the status of the loop is available, by suitably programming one of

the outputs (output 1, 2, 3) on the control unit, with the Oview programmer.

• Loop permanence time:

time during which the loop is occupied. Once this

time has passed, a recalibration is automatically activated to signal the free

loop.

• Loop operation mode:

if the function “Loop active” is enabled and the loop

command signal is ACTIVE, the behaviour of the barrier varies according to

the set “loop operation mode”:

- only opens (apartment block opens)

- only closes

- alt

- photo closes (PHOTO with total inversion)

• Calibration:

starts a calibration procedure; i.e. acknowledgement of the con-

nected loop. Note: the calibration automatically activates the parameter

“Loop power supply”

• Activation modes:

see

Table 16

(relay = loop command signal).

• Loop activation time:

is the time “

t

” linked to the operating modes

described in

Table 16

.

• Loop frequency display:

signals the fluctuation frequency of the loop

selected in Hz.

7.5.2 - Installation

WARNINGS

• It is advisable to install the magnetic loop near the barrier.

• The electric cables of the magnetic loops must be separated from the other

cables in the barrier (power supply, accessories, etc.).

• If the magnetic loops are connected to other barriers, it is necessary to posi-

tion them at least 1 m between each other.

•

Important!

– The magnetic loop must be fixed in a way to make it immobile

since any movement caused by an unstable floor could cause false tripping.

• The size of the loop must be defined depending on the application; it is nec-

essary to consider that the loop must be positioned at a distance of at least

20 cm from fixed metal objects and 1 m from moving metal objects (

fig. F

).

Note – To obtain optimal operation, it is worth using a loop that is the same

size as or smaller than the object to be detected.

• Usually the loop used for the passage of cars and trucks is rectangular in

shape, to be positioned 45° with respect to the route arranged for the pas-

sage of bicycles and motorbikes (

fig. G

).

Note – We recommend you cut the

45° corners of the outline on the floor to avoid breaking the cable.

•

IMPORTANT

– TO PREVENT INTERFERENCE,

THE CONNECTION CA -

BLES OF THE LOOP MUST BE TWISTED AT LEAST 20 TIMES A

METER AND THERE MUST BE NO JOINTS

. Should it be necessary to

extend the cable, weld the conductors and seal them with the thermo-shrink-

TABLE 14

Signal

Cause

Solution

1 flash

second pause

1 flash

Bluebus system error

At the start of the manoeuvre, the devices connected to Bluebus

do not correspond to those recognized during the self-learning

phase. One or more devices may be faulty; check and, if necessa-

ry, replace them. In case of modifications repeat the device self-

learning process (see paragraph 4.5).

2 flashes

second pause

2 flashes

Photocell activated

At the start of the manoeuvre, one or more photocells do not ena-

ble it; check to see if there are any obstacles.

3 flashes

second pause

3 flashes

Activation of Motor Force limiter

During the movement, the pole has experienced excessive fric-

tion; identify the cause.

6 flashes

second pause

6 flashes

Not used

–

7 flashes

second pause

7 flashes

Error in internal electric circuits

Disconnect all power circuits for a few seconds and then retry a

command; if the condition persists this may indicate a serious

fault with the board or motor wiring. Check and make replace-

ments as necessary.

8 flashes

second pause

8 flashes

Not used

–

9 flashes

second pause

9 flashes

Block automation

Send the command “Release automation” or control the manoeu-

vre with “High Priority Step Step”.

4 flashes

second pause

4 flashes

STOP input activation

At the start of the manoeuvre or during the movement, the STOP

input was activated; identify the cause.

5 flashes

second pause

5 flashes

Error on internal parameters in control unit

Switch off the power and turn it on again. If the error continues car-

ry out the “Total deletion of the memory” as described in chapter 7.1

and redo the installation; if the condition persists, there may be a

serious malfunction and the electronic board must be replaced.

Summary of Contents for M3BAR

Page 2: ......

Page 26: ......

Page 30: ...II 4 3 b a c d g h f e c a b...

Page 31: ...III 5 6 MBAR a c d b...

Page 32: ...IV 90 8 9 MBAR a b c a b 7 a b...

Page 33: ...V 180 10 11 LBAR c a a b...

Page 34: ...VI 13 14 12 LBAR c a b...

Page 35: ...VII 15 16 18 17...

Page 36: ...VIII 19 20 21 23 22...

Page 37: ...IX 24 26 25 28 1 cm 27 29...

Page 38: ...X 33 34 30 31 32 c a b c a b...

Page 39: ...XI 35 36 37 45 38 a b a b c...

Page 41: ...XIII 42 43 44 STOP 45 46 LIGHT 47...

Page 42: ...XIV 48 49 50 a b c...

Page 43: ...XV 51 52 a b...

Page 44: ...XVI 53 a b c d e f g...

Page 46: ...XVIII F1 F1 F2 F2 55...

Page 47: ......

Page 48: ...ISTML BARR01 4865_07 10 2011 www niceforyou com Nice SpA Oderzo TV Italia info niceforyou com...