EN

12

– English

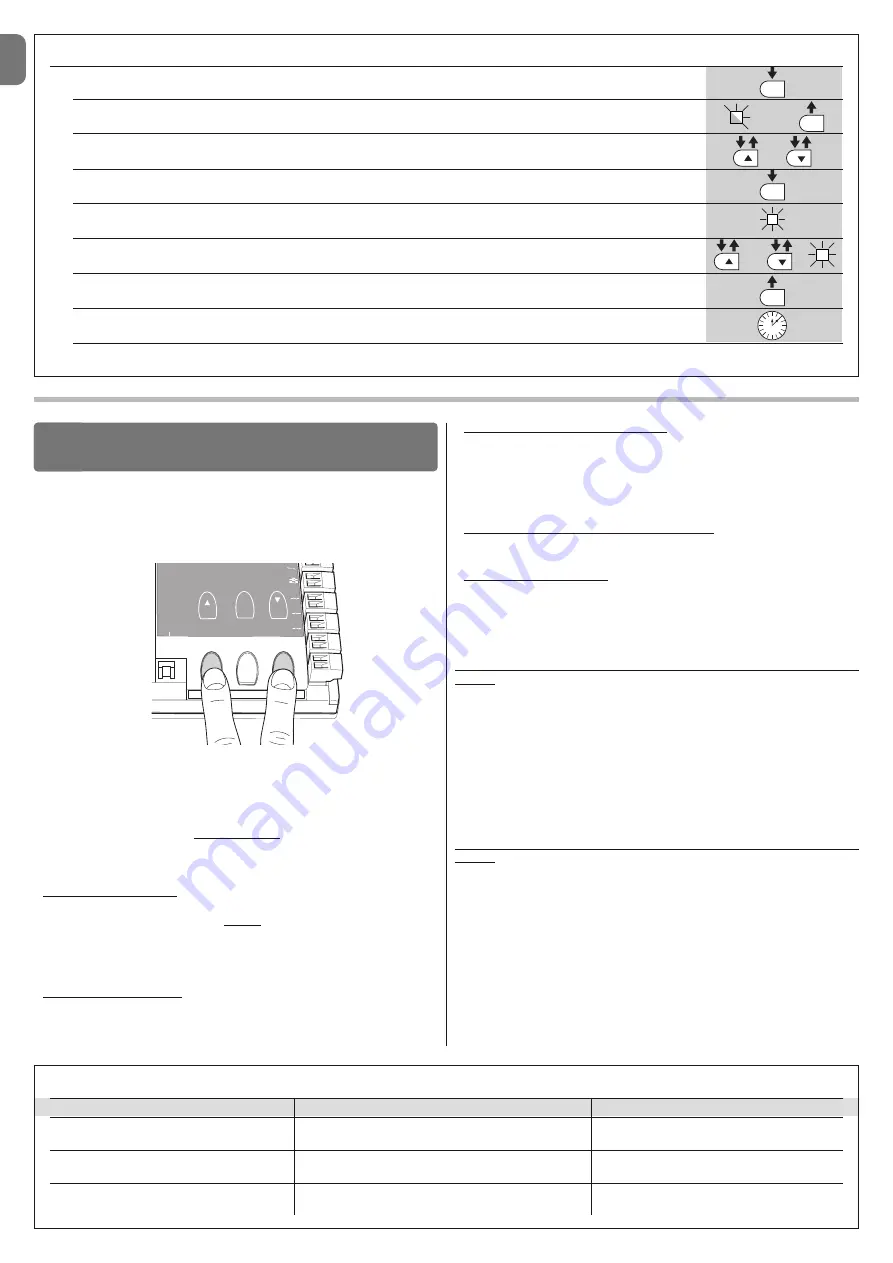

7.1 - Total deletion of control unit memory

It is possible to delete all memorised data on the control unit and reset it to the

original factory settings:

01.

Press and hold down “

▲

” and “

▼

” keys at the same time;

02.

Release the keys when all Led illuminate (after approx.3 seconds);

03.

When leds

L1

and

L2

start flashing, this means that the procedure is ter-

minated.

Note – With this procedure it is also possible to delete any errors remaining in

the memory.

Important

– This procedure does not delete the parameter regarding the

direction of motor rotation and the number of manoeuvres performed.

7.2 - Other functions

• “Always open” function

This function is a special feature of the control unit; it is associated with the

“Step Step” input and enables an “always open” command when the Step

Step command remains active for more than 3 seconds. This function is valid

for any setting of the Step Step input (see “SS Function” in

Table 8

).

For example, it can be used to connect a clock for programming permanent

opening of the barrier during a specific time band.

• “Move anyway” function

If one or more safety devices malfunctions or is out of service, this function

enables control of the barrier in “hold-to-run” mode (for details, see chapter

“operation manual”).

FURTHER DETAILS

7

• “Maintenance notification” function

This function enables notification of when an automation maintenance check is

necessary. The “Maintenance notification” parameter can be set by using the

Oview programmer. The maintenance notification is signalled via the Flash

flashing light or by the maintenance indicator according to the type of setting.

The signals emitted by the Flash flashing light and the maintenance indicator

are shown in

Table 10

.

• Check of number of manoeuvres performed

To check the number of manoeuvres performed, the Oview programmer is

required; parameters that can be checked under the item “Maintenance”.

• Manoeuvre counter reset

The manoeuvres can be reset at the end of the automation maintenance phase

and must be carried out by

deactivating

the “Maintenance indicator” function

related to the LIGHT output.

Note - Temporarily disconnect the device connected to the 1 LIGHT

output.

Procedure to

activate

the Maintenance indicator (when

it is not already

active

):

01.

Press and hold down the “

Set

”“ key for approx. 3 seconds;

02.

Release the key when LED “

L1

” starts flashing;

03.

Press the key “

▲

” or “

▼

” to move from the LED that is flashing to LED L4

(“LIGHT output” input LED);

04.

Press and hold the “

Set

” key through to completion of point 07;

05.

Wait approx. 3 seconds, until the LED of the programmed output illumi-

nates;

06.

Press keys “

▲

” or “

▼

” to move the lit LED on L8;

07.

Release the key “

Set

” and wait for the output for the timeout from the pro-

gramming procedure.

Procedure to

deactivate

the Maintenance indicator (when

it is not already

active

):

01.

Press and hold down the “

Set

”“ key for approx. 3 seconds;

02.

Release the key when LED “

L1

” starts flashing;

03.

Press the key “

▲

” or “

▼

” to move from the LED that is flashing to LED L4

(“LIGHT output” input LED);

04.

Press and hold the “

Set

” key through to completion of point 07;

05.

Wait approx. 3 seconds, until LED L8 illuminates;

06.

Press keys “

▲

” or “

▼

” to move the lit LED on a LED other than L8;

07.

Release the key “

Set

” and wait for the output for the timeout from the pro-

gramming procedure.

Now the maintenance notification has been cancelled.

Note – Reset the programming of the LIGHT output with the device to be used

and then reconnect it to the output.

Open

Stop

Set

Close

L1

Close

Open

PP

Stop

Bluebus

2

L2

L3

L4

L5

L6

L7

L8

BusT4

TABLE 9 - Programming procedure (second level functions)

01.

Press and hold down the “

Set

” key for approx. 3 seconds;

02.

Release the key when LED

L1

starts flashing;

03.

Press keys “

▲

” or “

▼

” to move from the flashing led to the led associated with the function to be modified;

04.

Press and hold the “

Set

” key through to completion of point 06;

05.

Wait approx. 3 seconds, until the LED representing the current level of the parameter to be modified illuminates;

06.

Press keys

▲

or

▼

to move the LED representing the value of the parameter;

07.

Release the “

Set

” key;

08.

Wait 10 seconds (maximum time) to exit the programming mode.

Note

– During this procedure, points 03 to 07 need to be repeated when programming other parameters during the phase itself.

SET

SET

SET

SET

L1

or

or

3 s

10 s

TABLE 10

Number of manoeuvres

Flash flashing light

Maintenance indicator

Below 80% of the limit

Normal (0.5 sec. lit - 0.5 sec. off)

Light on for 2 seconds at the start of the

opening manoeuvre.

Between 81% and 100% of the limit

Light on for 2 seconds at the start of the manoeuvre.

Flashing for entire duration of manoeuvre then

continuing as normal

Over 100% of the limit

At the start and end of the manoeuvre, remains lit

Always flashes

for 2 sec., then continues as normal.

Summary of Contents for M3BAR

Page 2: ......

Page 26: ......

Page 30: ...II 4 3 b a c d g h f e c a b...

Page 31: ...III 5 6 MBAR a c d b...

Page 32: ...IV 90 8 9 MBAR a b c a b 7 a b...

Page 33: ...V 180 10 11 LBAR c a a b...

Page 34: ...VI 13 14 12 LBAR c a b...

Page 35: ...VII 15 16 18 17...

Page 36: ...VIII 19 20 21 23 22...

Page 37: ...IX 24 26 25 28 1 cm 27 29...

Page 38: ...X 33 34 30 31 32 c a b c a b...

Page 39: ...XI 35 36 37 45 38 a b a b c...

Page 41: ...XIII 42 43 44 STOP 45 46 LIGHT 47...

Page 42: ...XIV 48 49 50 a b c...

Page 43: ...XV 51 52 a b...

Page 44: ...XVI 53 a b c d e f g...

Page 46: ...XVIII F1 F1 F2 F2 55...

Page 47: ......

Page 48: ...ISTML BARR01 4865_07 10 2011 www niceforyou com Nice SpA Oderzo TV Italia info niceforyou com...