Page-15

6. Allowable wrist load

CAUTION

Load fixed on the tip of wrist is regulated by “allowable payload mass”, “allowable static

load torque”, and “allowable moment of inertia”. Strictly keep the wrist load within each

allowable value. If wrist load exceeds the allowable value, this robot is out of guarantee.

Refer to the table of “2. Basic specifications” and following figures for the detail of each

specification.

■

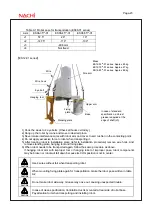

Torque map

Use the robot under condition that COG of wrist load falls on the range of following figure.

[Caution] Wrist load is greatly affected by robot speed and pose. If its weight is within the

permitted limit, vibration on arm or overload / over current error may occur. In that

case, slow down the robot speed or try to adjust acceleration (D1 to 3).

Also is tool constant was not set correctly, similar phenomenon may occur.

[Caution] Overhang amount such as moment and inertia written here is a dynamic limitation

which is determined by motor and reduction gear specification. Guaranteed

repeatability is at the center of mechanical interface surface. If long and low rigidity

tool is mounted and working point is far from the center, positioning repeatability

becomes worse or vibration on arm occur.

Allowable offset distance (Z direction) from bottom edge of shaft to tool COG is

100mm.

[Caution] Although tool is within the permitted limit, overload error may occur if robot

continuously moves to upward in extremely slow speed. In such case, robot speed

needs to be modified much faster.

[Caution]

Acceleration is automatically limited if tool COG becomes further from shaft center.

Allowable offset distance from shaft center to tool COG is

ES06 : 200mm or shorter ES12 240mm or shorter.

ES06-01 series

ES12-01 series

Rated moment of inertia

Shaft center

Shaft center

Maximum moment of inertia

Rated moment of inertia

Maximum moment of inertia