30

All parts maintained or repaired must be disconnected from the power supply.

You must check that the disconnected parts are not under voltage by means of

a bipolar measuring device, then connect them to the ground, and isolate

neighbouring parts under voltage!

Cut off voltage by turning the main switch to “0”, take out the key, and

disconnect the machine from the power supply.

Regularly check, or test, the filtration electrical equipment. Defects, loose

contacts or sloughed cables must be replaced immediately.

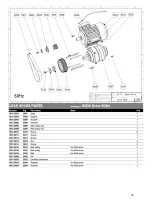

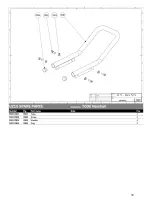

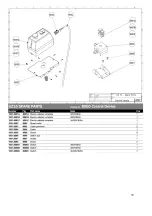

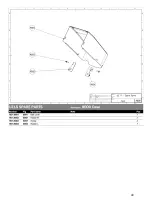

SPARE PARTS UZ15 Rapid

8.1 How to order spare parts

Orders for spare parts should contain the following information:

- machine type;

- serial number;

- required part description and its number;

- quantity.

8.2. Most wearing parts:

1)

cutting tool (can be ground) - pos. 2137

2)

lower cylinders (bearings) - pos. 2020

3)

work piece holder cylinders - pos. 3002

4)

transmission belt - pos. 5007 (5019)

5)

support bar - pos. 2002

6)

spindle feathers - 4 pcs. - pos. 4012

7)

cover sheet for drain off the chips - pos. 2004

8)

body of lower support – pos. 2001

9)

washer under the lower cylinder – pos. 2026

10)

bearings – pos. 2023

11)

Set of compensating washers (0,5 / 1 / 2mm) order.nr. 2140.

TIP:

The support bar fig 2002 guides the material towards the tool. All the bevelled material chafes

against this bar. Take into account that the bar will wear out eventually.

If this happens, you must repair the bar by welding it up, or replace it. If you fail to do so, the

machine may be damaged or the tool destroyed.

Bear in mind that the bar is conical.