2200M4JE-HO-iS2-N_2014.04.

Chapter 6 Troubleshooting

Screw Compressor i-series

6-3

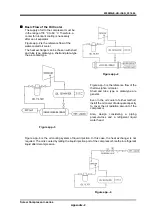

Symptom

Direct cause

Root cause

Action

05

Abnormally

high

pressure

(Abnormal

discharge

pressure)

Heat exchange

failure in condenser

(heat exchanger)

Heat transmission

tubes and/or fins

are contaminated

or blocked.

Clean and wash.

Depending on the contamination

level, use chemical cleaning.

Failure or water

dripping in fan

motor, thermo

switch, water

spraying pipes,

cooling water

pumps, etc.

Identify defective devices,

investigate causes of failure and

take necessary actions.

Then, replace failed device(s).

Faulty adjustment

of cooling

water/brine flow

In case of manually adjusted

valve, readjust the valve.

When an automatic control valve

(including wax valve) is used,

investigate the cause and take

necessary actions.

Other causes of

insufficient flow of

cooling water, etc.

Inspect filters installed on the

circulation route for clogging and

contamination, and take

necessary actions.

Inspect for leaks in circulation

routes, and take necessary

actions.

Inspect water supply

routes/mechanisms, and take

necessary actions.

If frozen, take measures such as

improvement of heat insulation or

increase of temperature.

Deficiency in heat

exchanger

performance

If the symptom is caused by

change in operating conditions,

re-examine the conditions for

improvement.

If the symptom is caused by

change in installation

environment, improve the

environment if possible.

In either case, if improvement

measure is difficult to be made,

add more heat exchangers or

increase their sizes.

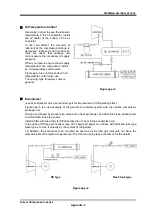

Non-condensable

gases mixed into

the system

Leak on low

pressure side

* There are also

cases where the

symptom was

caused by

corrosion in

suction

temperature

gauge protection

tube of the

compressor.

Perform a leak check, and take

necessary measures.

Air-purge the heat exchanger.