2200M4-JE-HO-iS2-N_2014.04.

Chapter 2 Compressor Specifications and Configuration

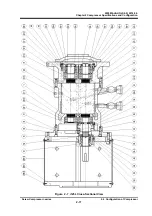

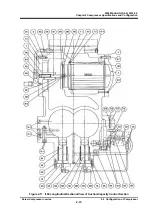

Screw Compressor

i-series

2.1 Features of i-Series Compressor

2-1

Chapter 2 Compressor Specifications and Configuration

2.1 Features

of

i-Series Compressor

i-series compressor enables designers to design highly reliable and most compact

refrigerating unit. It has a lot of features.

Centering is made unnecessary by mounting the motor using a flange.

By mounting the motor using a flange eliminates the need of the troublesome motor centering before

starting the equipment.

Suction strainer and check valve built-in compressor

This compressor has built-in suction strainer and check valve which enable easy maintenance.

No oil pump required in differential pressure oil supply system

This compressor employs roller bearings which let lubrication oil reserved in part even when the

machine is stopped. Accordingly, no lubrication failure will occur even with differential pressure oil

supply system which has no oil pump installed.

3-step (100%, 75%, 50%) unloader

As it has a 3-step (100%, 75%, 50%) unloader built-in, flow adjustment can be done easily.

Inverter-controlled speed control is available.

High efficiency, and low vibration and noise

Use of

original screw rotor profile attains high efficiency, and low vibration and noise.

2.2

Model Designation of the Compressor

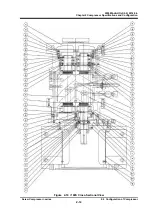

This manual describes i125*-* and i160*-* models.

The meaning of the type designation, which is engraved on the MODEL column of the compressor

nameplate, is as follows.

i 1 2 5 * - *

Specifications of Vi (volume ratio) of the discharge port, which is

L

(Vi=2.63),

M

(Vi=3.65)

or

H

(Vi=5.80)

Specifications of rotor length, which is

S

or

L

(i125) and

S

,

M

or

L

(i160)

Rotor diameter, which is 125 or 160

Indicates i-Series.