2200M4JE-HO-iS2-N_2014.04.

Chapter 5 Maintenance and Inspection

Screw Compressor i-series

5.5 Disassembly and Inspection

5-17

5.5.6 Bearing

Head

Though the case dividing method differs between i125 and i160,

the work flow is the same.

5.5.6.1 Disassembly

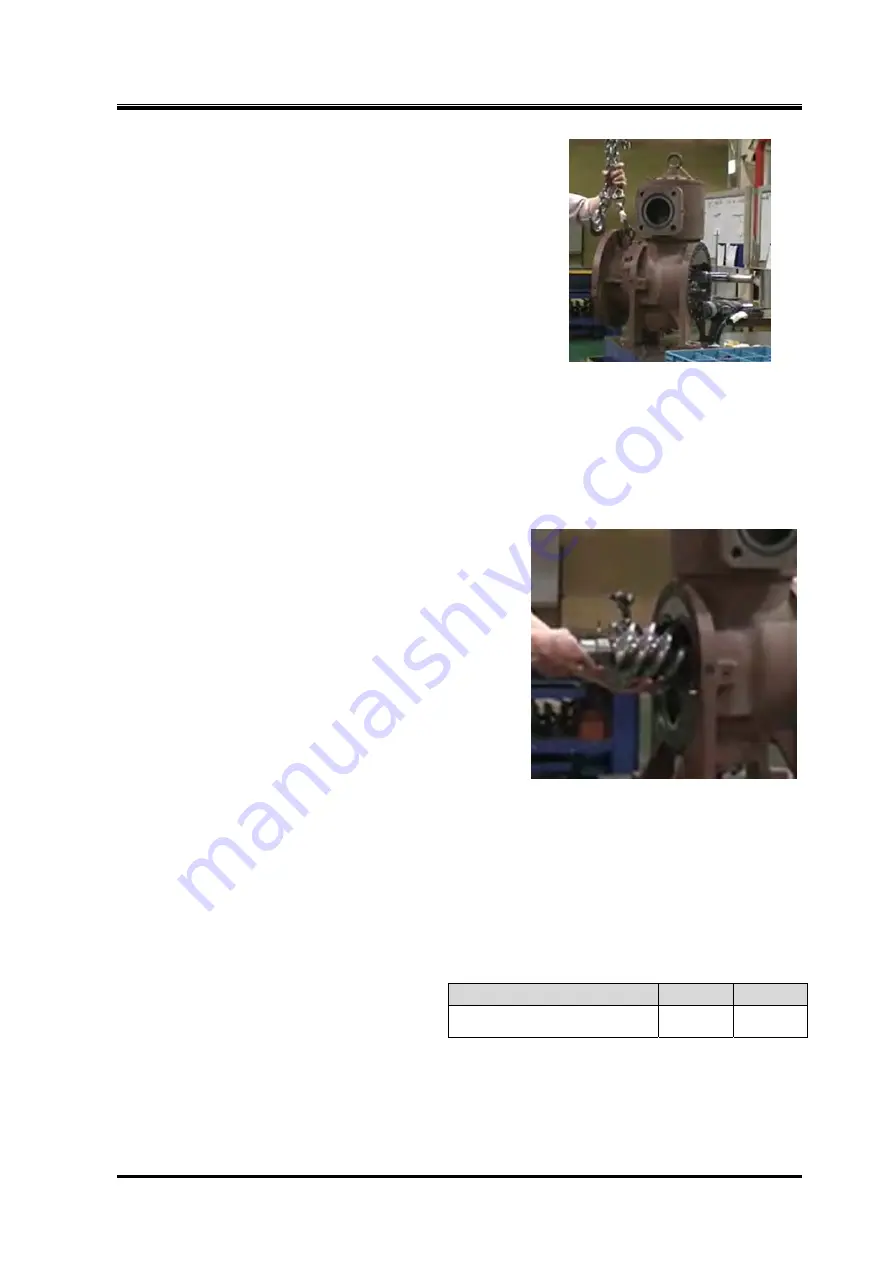

a) Attach lifting tools, remove all bolts

【

2-1

】

that hold the part to

the main rotor casing, and separate the part from the main

rotor casing. If bearing head gasket

【

12

】

is stuck, use a jack

bolt to remove it.

b) Remove bearing head

【

11

】

while taking care not to let it be

hit and damaged by the rotor shaft. Also take care not to let

the rotor fall off the main rotor casing.

5.5.6.2 Inspection

a) If the alignment pin is bent or worn, replace it with a new one.

b) The bearing head gasket must be replaced with a new one.

5.5.7 Rotors

Rotors

【

25

】

【

26

】

are heavy, precisely machined

components, which are the heart of the compressor.

Care must be taken not to get them damaged by dropping

or in other ways. Using damaged rotors may lead to

deterioration in performance or damage to the compressor.

5.5.7.1 Disassembly

a) When using the i125-series, remove snap ring

【

29-3

】

from the F rotor.

b) As it is heavy in weight, be careful when handling. As the i160-series rotor weighs more than 30 kg,

use lifting tools such as chain blocks and nylon belts. Pull out about two thirds of the rotor, attach a

belt around its outer circumference, and then pull out the remaining part of the rotor.

c) After pulling out the rotor, place it on V-blocks or the like to prevent damage to the outer

circumference.

d) Remove slotted set screw

【

31

】

.

5.5.7.2 Inspection

Check that the rotor is not extremely worn or

damaged.

Rotors stay almost free from wear during

normal operation.

If the rotor is found worn, check the cause and review the operating state to preventrecurrenceof the

problem.

If the part wears beyond the replacement standard shown in Table 5-10, performance will be

deteriorated. Replacement of the rotor is recommended.

Photo 013 Attach Lifting Tools

to Bearing Head

Photo 014 Pulling out the Rotor

measurement point

i125

i160

Rotor's outer diameter (mm)

127.475

163.175

Table 5-10 Rotor Replacement Standards