2202L5JE-DA-C5-N_2015.05.

3 Installation

Compound 2stage Screw Compressor

3.2 Installation Works

1612LSC Speed Increaser Type

3-5

3.2.5 Installation

3.2.5.1 Installation

Check that the surface of the package unit for compressor installation is even and horizontal. If it is not

flat and horizontal, tightening the bolts may lead to compressor deformation, and operation may be

affected.

3.2.5.2 Shaft Alignment between Compressor and Driving Machine

Turn off the main power and control power of the driving machine before shaft

alignment work between the compressor and the driving machine. Be careful so that

the power of instruments does not turn on during shaft alignment work. If the power

turns on during shaft alignment work, the driving machine starts moving and there is a

risk of being entangled with the rotating shaft.

At the time of turning ON/OFF each electric power breaker, make sure to prevent

electric shock.

For shaft alignment work between the compressor and driving machine, use designated

tools in normal condition. If a worn or damaged tool or a tool unsuitable for the work is

used, there is a risk of being injured.

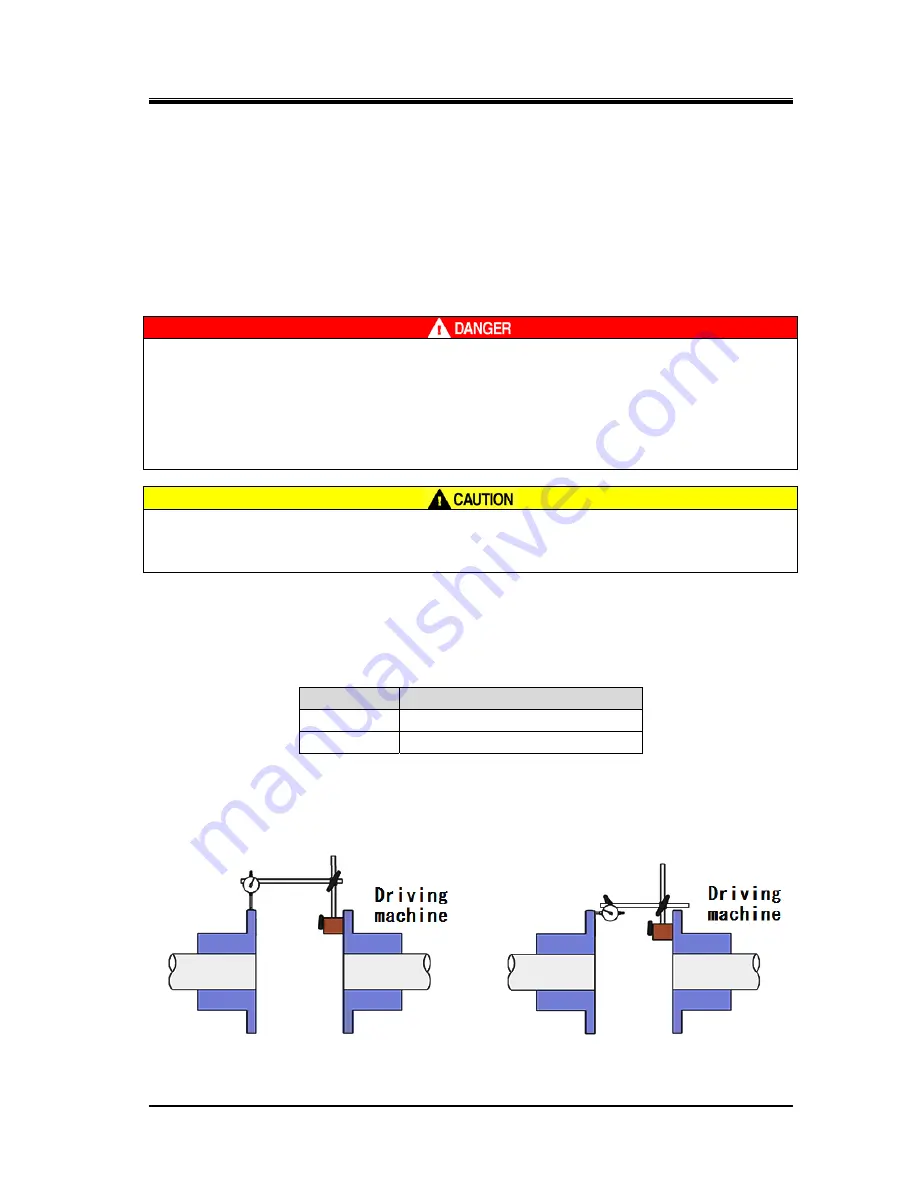

In the case shaft alignment between the compressor and the driving machine, be sure that the

deviations within the range shown in the Table 3–2. However, if alignment tolerance of the driving

machine side is more stringent than Table 3-2, please adjust to the request within the allowable value of

the driving machine side.

Table 3–2 Tolerance of Misalignment

Tolerance

Offset 6/100

mm

Angularity

3/100 mm (reference:

Φ

100 mm)

The Figure 3–3 and 3–4 show how to measure offset and angularity when performing the centering of

the shafts of the driving machine and this product using a dedicated hub, a dial gauge and a magnet

stand.

Figure 3-3 Measurement of Offset Figure 3-4 Measurement of Angularity