2202L5JE-DA-C5-N_2015.05.

5 Maintenance and Inspection

Compound 2-stage Screw Compressor

5.5

Reassembly

1612LSC Speed Increaser Type

5-62

g)

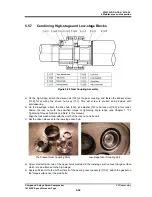

Bend the lock washer tooth into the notch of the lock nut to prevent loosening (following picture to

the left).

h)

Tighten the thrust bearing gland [190] with the hexagon head bolts [191] inserting spring washers

[192] in turn and evenly to the specified torque (above picture to the right).

The thrust bearing for the speed increaser gear spindle receives both lateral and axial loads.

i) Install the speed increaser gear side bearing [183] to the speed increaser gear casing by using two

eye bolts. In this case, force the side bearing into position while aligning the notch in it with the

bearing anti-rotation pin [184] located in the casing.

j)

Turn the speed increaser gear spindle [188] by utilizing the coupling key [91] to check that there are

no abnormalities.

With the dial gauge probe applied against the mechanical seal fitting portion of the speed increaser

gear spindle, turn the spindle to check for axial runout (picture below). The amount of axial runout

must not exceed 0.03 mm with all models.

Excessive runout occurs when the thrust bearing

mark is not at the correct side, and it occurs if

fastening the lock nut performed without changing

the position of the lock nut wrench (i.e., the uneven

fastening of the lock nut).

Moreover small particles of dirt trapped between

parts may cause excessive runout.

Precise control of runout is important since the

performance and the life of the mechanical seal

are significantly affected if its amount exceeds the

limit.