2202L5JE-DA-C5-N_2015.05.

5 Maintenance and Inspection

Compound 2-stage Screw Compressor

5.5

Reassembly

1612LSC Speed Increaser Type

5-53

c) Secure the bearing gland by tightening the four screws evenly to the specified tightening torque

gradually. Tightening each screw to the specified torque at once will lead to uneven tightening so

tighten each screw little by little.

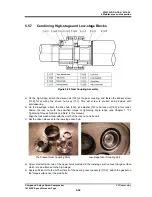

c) Then, read the dial gauge measurement. This value is the actual end clearance.

If the end clearance is outside the specified value, perform the adjustment work described in the

next section. If the end clearance is within the specified value, turn the M rotor shaft by hand and

confirm the smooth turning without uneven tightening. And then perform the measurement of the

run-out of the rotor shaft described in next section (3).

Figure 5-17 End Clearance Measurement

Table 5-11 Thrust Bearing Gland Tightening Torque

Compressor Model

Tightening Torque

N·m

kgf·cm

1612LSC

speed increaser type

High-stage 30

300

Low-stage

M 50 500

F 40 400

Tightening by Bearing Gland

1. There are two types of high-stage thrust bearing gland. The one on the male rotor has structure

which flows lubrication oil into the gear coupling.

2. The low-stage thrust bearing gland, structure is the same in M rotor side and F rotor

side, size is incorrect. Hexagon head bolt to tighten also different.