Installation

Ultima Hooklift

01/2020

27

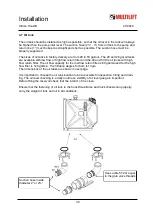

4 Hydraulic system

4.1 Safety precautions when installing hydraulic system

The hydraulic system may only be installed by qualified personnel.

Observe the utmost cleanliness (16/13 ISO 4406) while installing the hydraulic compo-

nents. All hoses, pipes etc. components must be cleaned and free from machining an

cutting burrs which can cause damage or malfunction to the hydraulic system.

The hooklift has been tested at the factory under maximum permitted operating pressure.

The pressure limiting cartridges of the control valves are not to be changed or adjusted

due to risk of injuries to persons or damages to property in the surrounding area.

The maximum operating pressure of the hydraulic system is 4351 psi (300 bar). Never

touch the hoses or couplings when the system is under pressure.

When raised to tipping position or with the middle frame raised, the frames must always

rest on a suitable strong support before working near the unit to prevent unintentional

lowering of frames and injuries to persons.

The hydraulic oils are hazardous and must be handled according to local legislation and

instructions. The safety data sheet of the hydraulic fluid must be available to the people

working with the hydraulic system.

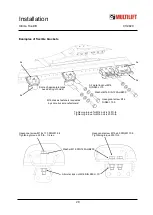

4.2 Specifications of the hydraulic system

The recommended oil flow and oil volumes for individual hooklift size is shown in the table next

page.

The minimum size of oil tank is equal to one minute pump flow. The recommendation is to in-

stall as large oil tank as possible in front or side of the hooklift. The oil tank sizes available from

the factory are between 20 - 53 gal.

The hooklift is delivered tested and cylinders filled with oil. The approximate amount of oil in

the hooklift is shown in the table. The hydraulic fluid used in testing is ISO VG 22. Alternatively

the oil is biodegradable ISO-L-HEES VG 32 which is then mentioned with a label in the oil tank

and bracket of control valve.

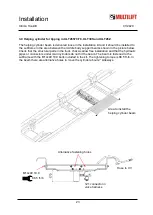

The amount of hydraulic fluid needed to add in the system during the installation is:

Oil tank pump pressure / suction line volume.

The diameter of suction, pressure and return lines are the minimum allowed diameters. Check

the instructions of the pump manufacturer on the recommended pipe and hose diameters.

The hydraulic fluid quality in factory delivered hooklift is

ISO VG 22

OR

biodegradable ISO-L-HEES VG 32

Summary of Contents for ULTIMA S

Page 2: ...Installation Ultima Hooklift 01 2020 2 ...

Page 35: ...Installation Ultima Hooklift 01 2020 35 Oil tank dimension steel tanks ...

Page 36: ...Installation Ultima Hooklift 01 2020 36 Oil tank dimension aluminium tanks ...

Page 56: ...Installation Ultima Hooklift 01 2020 56 Camera view examples High Bogey Rear ...