Due to the Morley enclosure’s presence of “predrilled” holes, it is necessary to

fabricate a shim/spacer to properly center the board mounted DC jack.

The spacers can be fashioned from two pieces of etched circuit board scrap.

Drill holes and file slots to accommodate the jack pins in two pieces of circuit

board. Cut both pieces to extend past the two sides and the rear of the jack.

The spacers should be flush with the front of the jack.

Using a file and emery cloth, reduce the combined thickness of the two shims

for a total thickness of 2mm. This spacer thickness allows for centering the

jack with the existing hole and leaves an ample amount of the jack pins

protruding through the flanger PC board for adequate soldering.

Secure one shim to the bottom of the jack with 5 minute epoxy. Secure the

second shim onto the first with epoxy. Now secure the jack with attached 2mm

spacer onto the flanger circuit board with epoxy.

This method of attachment will also alleviate pressure exerted on the jack pins

and solder joints which are the usual points of failure.

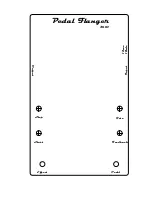

PEDAL FLANGER (MUTRON)

DC Jack Spacer

Fabrication & Installation

Summary of Contents for Pedal Flanger 3007

Page 5: ......

Page 6: ......

Page 7: ......

Page 8: ...PEDAL FLANGER MUTRON Main Board Overlay...

Page 10: ...5 32 in 6 50 in 134 5mm 164 7mm...

Page 11: ...111 6mm 4 41 in 3 54 in 89 9mm...

Page 18: ...4 5 6 1 2 3 9 8 7 4 5 6 1 2 3 SW2 SW1 PEDAL FLANGER MUTRON OFF BOARD WIRING LEGEND...

Page 34: ...Feedback Rate Start Stop Pedal Flanger 3007 Input Output Effect Pedal 12vac 18vdc...