28

Installation

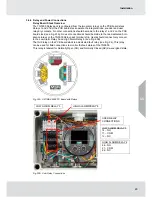

(10) Replace the board stack by aligning the four metal standoffs with the four holes inside

the TG5000 housing on the mounting plate. Push firmly on the board stack where

indicated (see Fig. 22).

Fig. 22

Highlighted Areas Show Where to Press when Replacing a Board Stack

NOTICE

Ensure that the electronics assembly is fully engaged in the mounting holes. If not fully seated,

the touch interface performance can be negatively affected

NOTICE

Avoid pressing on the left and right areas where the LEDs are located. Pressing directly on the

display will damage the display and will void the warranty.

Care must be taken to insure the TG5000 label inside overlay surface is free of smudges/dirt and

grease. Dirt and grease can interfere with the touch interface of the display.

US

Summary of Contents for TG5000

Page 1: ...Operating Manual TG5000 Gas Monitor Order No 10212126 L Y REV 0 US ...

Page 36: ...36 Operation US ...

Page 46: ...46 Operation US ...

Page 62: ...62 Maintenance US ...

Page 63: ...63 Maintenance US ...

Page 64: ...64 Maintenance US ...

Page 70: ...70 Appendix Calibration Guide and Additional Gases US ...

Page 71: ...71 Appendix Calibration Guide and Additional Gases R 32 US ...

Page 72: ...72 Appendix Calibration Guide and Additional Gases US ...

Page 75: ...For local MSA contacts please visit us at MSAsafety com ...