26

MAIN BURNERS

The connection for the burners is accessed by

removing the Venturi cover. The burners are

accessed by removing the grids and carriage.

The burner valves are accessed by removing

the control panel cover.

CAUTION: Turn off the gas supply at the

main shutoff valve that is next to the broiler

before attempting to loosen any gas

connections.

Burner Assembly, Orifice, and Venturi

1. Remove the Venturi cover as described in

COVERS AND PANELS.

2. Remove the ceramic radiants from each

side of the main burner to be replaced.

3. Loosen the set screw that attached the main

burner to the Venturi assembly.

4. Slide the main burner out of the broiler.

5. If the Venturi or orifice is to be replaced,

disconnect the gas input to the Venturi.

Remove the gasket. Replace the gasket

every time the Venturi or burner is removed.

6. Loosen the lock nut so that the Venturi can

be removed from the bracket.

Figure 8. Burner pilot assembly

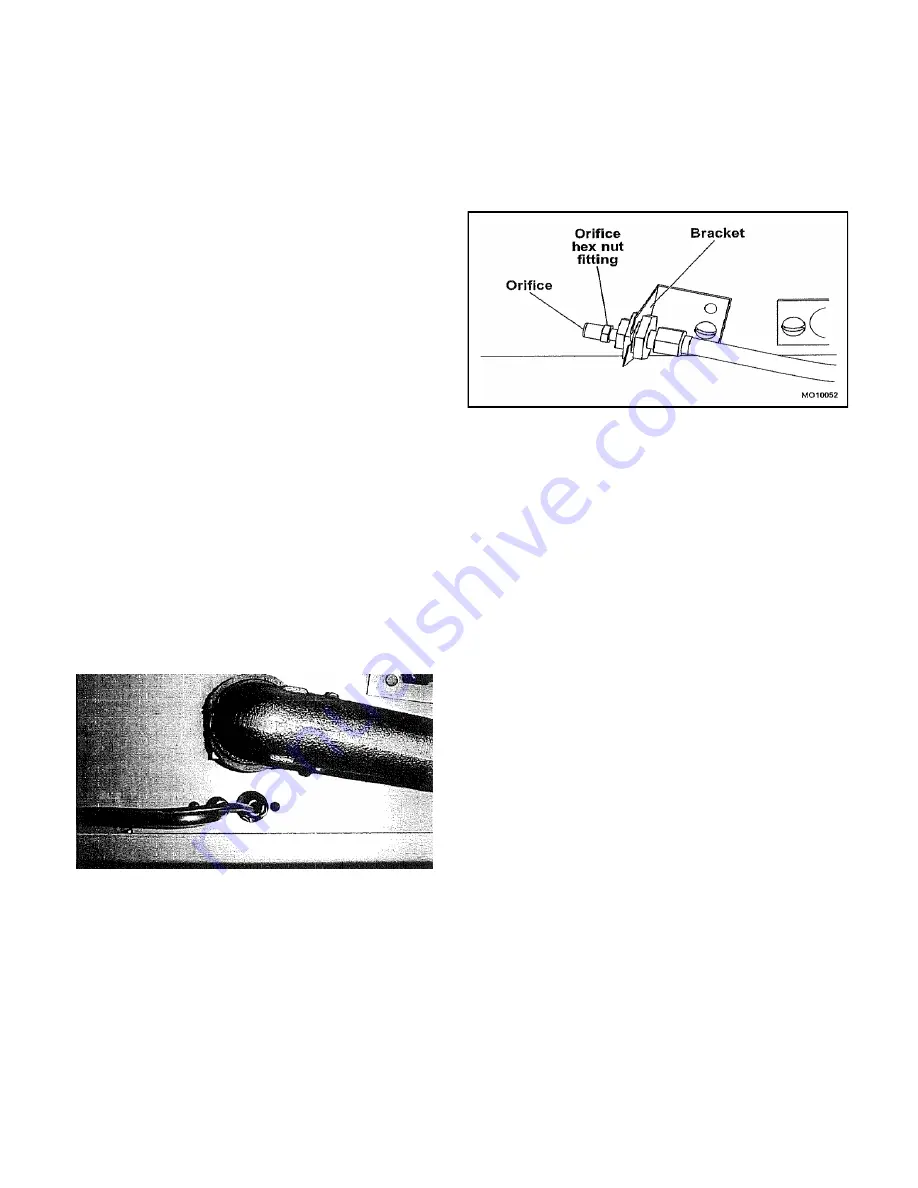

7. Remove the orifice hex nut fitting from the

Venturi.

8. Remove the orifice from the hex nut fitting.

NOTE: Make sure the pipe joint compound or

pipe thread sealant that is being used is

resistant to the corrosive actions of liquefied

petroleum gases.

9. Reassemble by reversing procedure.

WARNING!

All gas joints disturbed during servicing

must be checked for leaks. Check with a

soap and water solution (bubbles). DO NOT

use an open flame.

Figure 9. Orifice Assembly

Burner Valve Removal/Replacement

The burner valves are located on the manifold

behind the control panel cover.

CAUTION: Turn off the gas supply at the

manual shutoff valve that is next to the

broiler before attempting to loosen any gas

connections.

1. Remove the control panel cover as

described under COVERS AND PANELS to

access the burner valve.

2. Disconnect the gas line, pilot line, and ther-

mocouple from the back of the burner valve.

3. Unscrew the burner valve from the manifold.

4. Install the new burner valve.

NOTE: Make sure that the pipe joint compound

or pipe thread sealant that is being used is

resistant to the corrosive actions of liquefied

petroleum gases.

5. Connect the gas line, pilot line, and

thermocouple to the back of the valve.

6. Turn the main gas shutoff valve to the

broiler to the ON position.

WARNING

All gas joints disturbed during servicing

must be checked for leaks. Check with a

soap and water solution (bubbles). DO NOT

Summary of Contents for E136W36

Page 19: ...19 C36 C45 EXPLODED VIEW...

Page 21: ...21 36W366 43W36 EXPLODED VIEW...

Page 33: ...33...

Page 36: ...36...