Delta softstart RevB17 26-9-17

9

6.0 ISOLATION

1

In an emergency, switch off at the mains wall isolator, or the machine’s

emergency stop button. To release the emergency stop button, turn clockwise.

7.0

CLEANING INSTRUCTIONS

NOTE:

-Cleaning mu

st be carried out by fully trained personnel only.

-Isolate machine from mains supply before carrying out any cleaning.

-Do not steam clean or use a jet of water,

except in the rotary template drive gear compartment

All the outer surfaces of the machine should be wiped over with warm soapy water.

Do not use any form of caustic detergent or abrasive.

BETWEEN PRODUCT MIX CHANGES

1

The hopper, hopper pump, template, nozzles etc should be removed from the

machine and dismantled for thorough cleaning.

2

Prior to removing the hopper or template, the guards must be hinged up and

propped into the appropriate position.

3

Slacken template clamp strip nuts and remove fitted template from hopper

pump assembly by sliding out to avoid subsequent damage.

4

To reduce weight and bulk, separate and remove hopper body from hopper

pump assembly whilst still on the machine. Unscrew the nuts holding the

hopper body to the hopper pump to reveal the ‘0’ sealing ring. Ensure seal is

not damaged during cleaning.

5

Unscrew hopper retaining pin and remove hopper pump assembly from

machine to

separate cleaning area.

ROTARY TEMPLATE

DRIVE

FRONT AND REAR GUARDS

HINGED UP

HOPPER RETAINING PIN

EMERGENCY

STOP BUTTON

Summary of Contents for DELTA DEPOSITOR 40

Page 2: ...Delta softstart RevB17 26 9 17 2...

Page 22: ...Delta softstart RevB17 26 9 17 22 17 0 DELTA DEPOSITOR RECOMMENDED SPARES LIST...

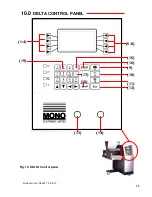

Page 27: ...Delta softstart RevB17 26 9 17 27 18 0 ELECTRICAL DIAGRAMS...

Page 28: ...Delta softstart RevB17 26 9 17 28...

Page 29: ...Delta softstart RevB17 26 9 17 29...

Page 30: ...Delta softstart RevB17 26 9 17 30...

Page 31: ...Delta softstart RevB17 26 9 17 31...

Page 32: ...Delta softstart RevB17 26 9 17 32...

Page 33: ...Delta softstart RevB17 26 9 17 33...

Page 34: ...Delta softstart RevB17 26 9 17 34...

Page 35: ...Delta softstart RevB17 26 9 17 35...

Page 36: ...Delta softstart RevB17 26 9 17 36...