Delta softstart RevB17 26-9-17

11

8.0 OPERATING CONDITIONS

Make sure the depositor is used on a level floor to achieve best results.

Ensure flat trays of consistent length, width, material and edge dimensions are used to

obtain the best product results and consistent operating from the

DELTA.

9.0 OPERATING INSTRUCTIONS

FITTING THE HOPPER

CAUTION SHOULD BE TAKEN WHEN FITTING HOPPER PUMP AS WEIGHT EXCEEDS 25KGS.

1

Hinge up front and rear hopper guards and prop up.

To reduce weight and bulk, fit the complete hopper assembly in two stages

- first the hopper pump assembly, then the hopper body with its detachable top guard.

2

Align hopper pump drive gear with drive shaft and slide hopper on support bars

until fully up against bulkhead. Screw in hopper retaining screw once the hopper

is positioned correctly.

DO NOT OPERATE MACHINE WITHOUT TEMPLATE FITTED.

FITTING A NON-ROTARY TEMPLATE

1

Hinge up front and rear hopper guards and prop up.

2

Select template and nozzles required.

3

Screw nozzles into threaded nozzle tube on templates.

4

Slide template into matching recess at base of hopper pump until the stop

engages.

5

Tighten nuts on clamp strip on underside of hopper pump to secure template.

Leakage of mix will occur if the nuts are not securely tightened.

6

Lower front and rear hopper guards.

Hopper pump drive shaft alignment

The use of templates and/or accessories not produced or supplied by MONO Equipment will invalidate the

machine’s warranty

Summary of Contents for DELTA DEPOSITOR 40

Page 2: ...Delta softstart RevB17 26 9 17 2...

Page 22: ...Delta softstart RevB17 26 9 17 22 17 0 DELTA DEPOSITOR RECOMMENDED SPARES LIST...

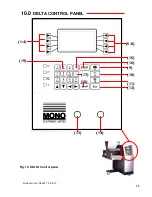

Page 27: ...Delta softstart RevB17 26 9 17 27 18 0 ELECTRICAL DIAGRAMS...

Page 28: ...Delta softstart RevB17 26 9 17 28...

Page 29: ...Delta softstart RevB17 26 9 17 29...

Page 30: ...Delta softstart RevB17 26 9 17 30...

Page 31: ...Delta softstart RevB17 26 9 17 31...

Page 32: ...Delta softstart RevB17 26 9 17 32...

Page 33: ...Delta softstart RevB17 26 9 17 33...

Page 34: ...Delta softstart RevB17 26 9 17 34...

Page 35: ...Delta softstart RevB17 26 9 17 35...

Page 36: ...Delta softstart RevB17 26 9 17 36...