Delta softstart RevB17 26-9-17

17

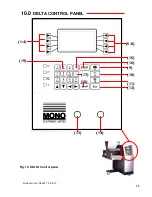

12.0 OPERATIONAL CONTROLS

(See fig.10)

Emergency stop button (13)

Isolates all electric circuits immediately. To release the emergency stop button, turn clockwise.

NOTE: ONLY USE IN AN EMERGENCY.

TO STOP THE MACHINE WHEN IN USE, ONLY USE STOP BUTTON (16)

.

Start button (14)

Activates all electric circuits. This must be pressed initially to apply power to the control panel.

Either “AUTO” button (11) or “MANUAL” button (10) followed by start button (14) are then pressed

to apply power to the motors and start the program.

Stop button (16)

Will stop the machine cycle immediately in either AUTOMATIC or MANUAL modes. When

the machine is started again in either of these modes, it will begin to deposit at the start of a

deposit cycle, no matter at what stage of the cycle the machine was stopped.

If pressed when depositing head of machine is too low to remove tray, the manual button

(10) then start button (14) must be pressed in order to reset and raise head height and eject

tray, which is currently on table

.

Prime button (9)

Then press start button (14),

primes the pump gears and nozzles with product

after the hopper has been loaded with mix and the hopper guards have been closed. The deposit

motor will

run as long as the button is pressed. The prime button can also be used to aid the engagement

of hopper gears to drive shaft and rotary template drive gear. Prime button (9) will only function

in edit/create or run menu.

Auto button (11

).

Then press start button (14),

This automatic operation is activated by the tray sensor on the tray guide and allows the

machine to be constantly fed with trays without the operator having to touch the control panel.

The machine will operate when a tray is placed on the table and will stop cycling when each

tray of deposit is completed. A minimum space of 50mm between trays allows for correct tray

positioning.

To halt the automatic cycle press the stop button.

Manual button (10)

Then press start button (14),

initiates the machine to cycle for one tray only. On completion of the tray, it is returned to the

front of the machine and stopped, and the depositing head is returned to a pre-determined

height to accept the next tray, which must be subsequently placed on the table and the above

procedure repeated.

To halt the manual cycle press the stop button.

Summary of Contents for DELTA DEPOSITOR 40

Page 2: ...Delta softstart RevB17 26 9 17 2...

Page 22: ...Delta softstart RevB17 26 9 17 22 17 0 DELTA DEPOSITOR RECOMMENDED SPARES LIST...

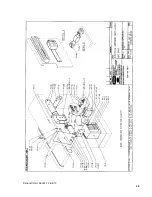

Page 27: ...Delta softstart RevB17 26 9 17 27 18 0 ELECTRICAL DIAGRAMS...

Page 28: ...Delta softstart RevB17 26 9 17 28...

Page 29: ...Delta softstart RevB17 26 9 17 29...

Page 30: ...Delta softstart RevB17 26 9 17 30...

Page 31: ...Delta softstart RevB17 26 9 17 31...

Page 32: ...Delta softstart RevB17 26 9 17 32...

Page 33: ...Delta softstart RevB17 26 9 17 33...

Page 34: ...Delta softstart RevB17 26 9 17 34...

Page 35: ...Delta softstart RevB17 26 9 17 35...

Page 36: ...Delta softstart RevB17 26 9 17 36...