CHAPTER 2: INSTALLATION

MODEL 250DP DUAL PULSE

RESISTANCE WELDING POWER SUPPLY

2-8

990-280

2-Level Footswitch

When a 2-level footswitch is pressed to the first level, the weld head will close and apply force to the

workpiece. At this point, if the operator does not press further (harder) and actuate the second level, the

footswitch can be released so that the workpiece can be re-positioned. Once the second level has been

actuated, a 2-level footswitch will operate in the same manner as a 1-level footswitch.

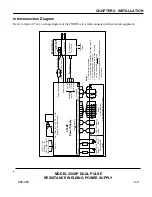

Remote Schedule Selection

A 15-pin, subminiature D-type CONTROL SIGNALS connector, located on the rear panel, is provided for

seven single-pole inputs which are used to:

x

Remotely select Weld Schedules 1 through 127 in a binary sequence.

x

Remotely inhibit (prevent) the flow of weld current, which is the same function provided by the front

panel WELD/NO WELD Switch.

x

Invoke the emergency stop condition, which abruptly terminates the welding sequence. Refer to

Appendix A, under

Control Signals,

for detailed connector information.

Relay Outputs

Two output relays can be used to provide status (timing) signals to external devices. They can also provide

an on (closed) state during a Run state or if there is an alarm.

Relay 1 can also be used to control a second 24 VAC air actuated weld head. (Refer to Air Actuated Weld

Head Connections for the appropriate hook-up connections and figure 4-5 for appropriate jumper

connections.)

Relay 2 can provide a 5 to 50 VDC signal.

When used to provide status (timing) signals, the relays can be independently programmed as follows:

x

In Basic Mode, each relay can be programmed on (closed) or off (open) during either of the two weld

periods.

x

In Roll Spot Mode, each relay can be programmed on (closed) or off (open) during either of the two

weld periods or during the cool period (between each spot weld cycle).

x

In Repeat Mode, each relay can be programmed on (closed) or off (open) during either of the two weld

periods or during the off period (between each Repeat cycle).

In all of the above cases, if the relay is programmed to be on (closed), it will close at the beginning of the

scheduled period and open at the end of that period. If scheduled to be closed during any successive

periods, it will not open at the end of the first period, but will remain closed during both (or all) periods for

which it is scheduled to be closed.