CHAPTER 4: GETTING STARTED

MODEL 250DP DUAL PULSE

RESISTANCE WELDING POWER SUPPLY

4-6

990-280

15 If appropriate, modify the Weld Sentry program. To develop a Weld Sentry program, use the Weld

Sentry basic setup option, which is accessed by pressing [MENU] and selecting WELD SENTRY

followed by BASIC SETUP.

16 If you want to see a graphical representation of a weld schedule, select DISPLAY GRAPH OF LAST

WELD from the Weld Sentry print utility menu.

17 If you are using a second air actuated weld head:

a Connect the second air head to Air

Valve Driver 2.

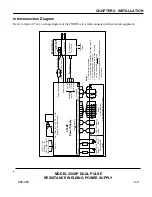

b There are two jumper headers, E10 and

E11, located on the lower right hand

area of the control printed circuit

board. Re-jumper the headers to the

dual air configuration as shown in

figure 4-5.

c Press [MENU] and select OPTIONS.

d Change the weld head type to DUAL

AIR.

e Press [PROGRAM] and move the

cursor to the RELAY 1 field.

f

Press [CHNG] until AIR HEAD 2 is displayed.

g Press [SAVE] to store the changes.

E10

E11

E10

E11

Single Air Head

Dual Air Head

Jumper

Jumper

Jumper

Jumper

Figure 4-5. Weld Head Configuration Jumper

Selection